| Fabric name | Taffeta |

| Fabric also known as | Paper taffeta, shot silk |

| Fabric composition | Silk, rayon, or polyester |

| Fabric breathability | Very breathable |

| Moisture-wicking abilities | Low |

| Heat retention abilities | Low |

| Stretch ability (give) | Low |

| Prone to pilling/bubbling | None |

| Country where fabric was first produced | Persia |

| Biggest exporting/producing country today | India |

| Recommended washing temperatures | Hand wash cold or dry clean |

| Commonly used in | Wedding gowns, evening wear, blouses, party attire, curtains, insulation, sleeping bags |

Gianna Silk Taffeta Fabric

Gianna Silk Taffeta Fabric

What Is Taffeta Fabric?

Taffeta is a crisp, lightweight fabric that is commonly used to make a variety of types of high-end women's apparel. This plain woven fabric is smooth to the touch, and it can be made from a variety of different materials.

The word "taffeta" is derived from tafta , which means "twisted woven" in Persian. While it's true that taffeta fabric is made by twisting yarn as it is woven, many other fabrics are also made with this method, which means that the starched and shape-retaining qualities of taffeta are more representative of its unique attributes than its name.

Traditionally, taffeta was made from silk, but with the advent of synthetic fibers in the 20th century, textile manufacturers started making this fabric from materials like rayon and polyester. While it's still possible to find silk taffeta fabric, it's much more common to find versions of this fabric that are made from polyester.

Deep Orange Silk Taffeta Fabric

Deep Orange Silk Taffeta Fabric

While the term "taffeta" has been used to describe lightweight silk garments for close to a thousand years, it's unclear whether the taffeta of the distant past resembled the type of fabric that goes by this name today. This fabric shows up multiple times throughout history; for instance, it's reported that tabby cats were originally named for their resemblance to a certain type of striped taffeta fabric.

Taffeta was also used in certain aviation experiments during the 18th century. In recent times, taffeta fabric has even been used in artificial blood vessel experiments due to its paper-thin texture and durability.

One of taffeta fabric's most notable attributes is its shape retention. Many other thin fabrics tend to lose their shape as they are worn, but taffeta's starched texture makes it possible to shape this fabric into a number of different forms that don't deform or become distorted over the course of an evening.

When taffeta is worn, it produces a relatively noisy rustle due to its crispness. Depending on the type of taffeta that is worn, this fabric may produce an iridescent effect when its wearer moves, or its paper-thin texture may be caught on every current of air that moves through a room. This fabric's unique qualities have earned it a position in public perception as a luxury textile, and this perception has persisted even as traditional taffeta fabric materials, such as silk, have been widely replaced with polyester and rayon.

How Is Taffeta Fabric Made?

This type of fabric is made with a variety of different techniques depending on the type of material that is used in its production. Silk production, for instance, involves the cultivation and harvesting of silkworm cocoons. This process is highly environmentally sustainable, but it results in the deaths of silkworms.

Once silkworm cocoons are boiled, they are unraveled or "reeled," and the resulting thread is then soaked in a mild, non-toxic solution. Finally, this thread is spun into yarn, and it may be dyed at this point. However, certain types of taffeta fabric are dyed after a bolt of fabric has already been woven.

While some taffeta fabric is made from semi-synthetic substances like cuprammonium rayon, it's much more common to find this product made from polyester. Since polyester is a fully synthetic textile fiber, its production process varies widely from that which is used to make silk.

Jumbo Taffeta Fabric Flower – Champagne

Jumbo Taffeta Fabric Flower – Champagne

Polyester is derived from a compound called ethylene, which is a constituent part of petroleum. This ethylene is reacted with dimethyl terephthalate at a high temperature, which produces a monomer alcohol. This monomer is then combined with terephthalic acid to produce the polymer known as polyester.

This molten substance is then extruded through a slot and allowed to cool into long ribbons. These ribbons are then chipped, and they are melted again. Next, this molten polyester is extruded through a spinneret, and the resulting strands of textile fiber are allowed to cool before they are stretched in a process called "drawing." Lastly, the drawn polyester fibers are dyed or subjected to flame retardant or antistatic treatments.

Once raw textile fiber is acquired, taffeta fabric can be formed with either hand weaving or an industrial weaving machine. A special twisting procedure is used to provide the crisp and lightweight qualities of this fabric. Depending on the type of taffeta fabric that is produced, it may be dyed before or after weaving.

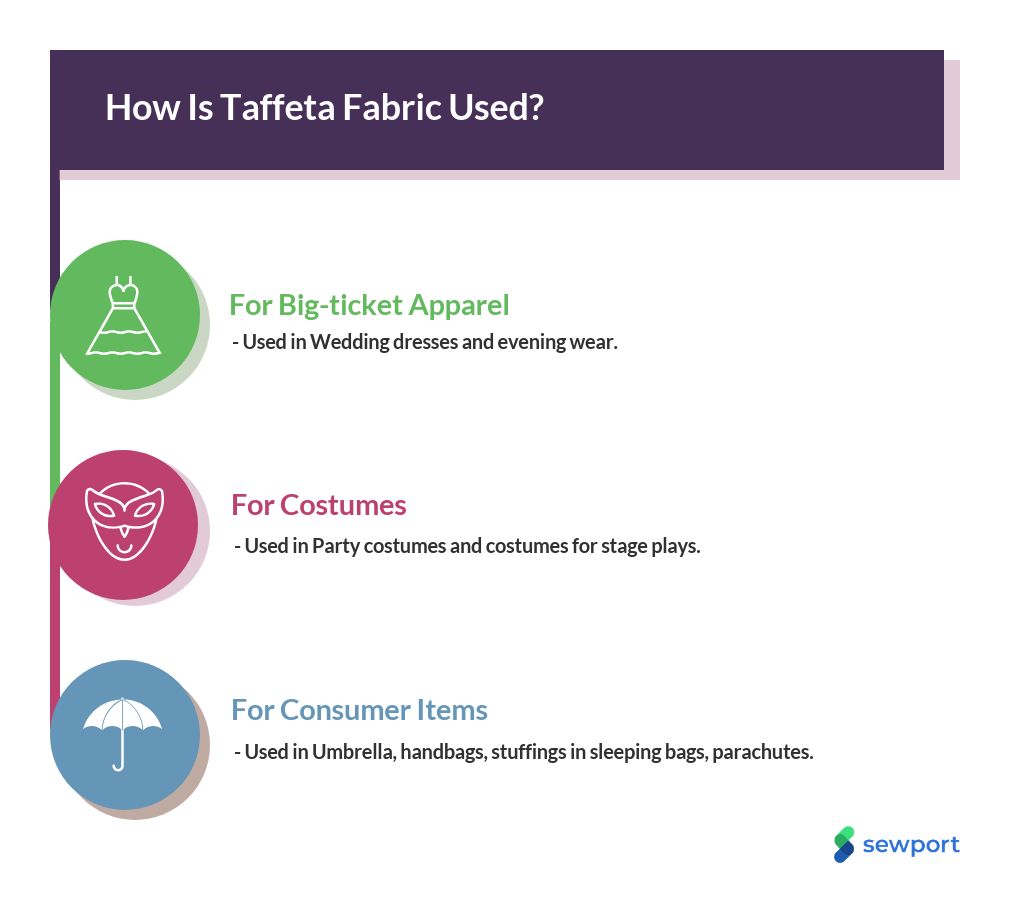

How Is Taffeta Fabric Used?

Taffeta is considered to be a luxury fabric, and it is relatively prone to damage. Therefore, it isn't commonly used in everyday clothing; on the contrary, it is more common to see this type of fabric used in big-ticket apparel like wedding dresses and evening wear.

Due to its iconic rustling and lightweight heft, this fabric is commonly used in party attire of all kinds. For instance, it is frequently used to make party costumes, and it also may be used to make costumes for stage plays. Due to its softness, piece-dyed taffeta is sometimes used to make linings for jackets and coats.

Beyond apparel, taffeta fabric is also used to make a number of consumer items. For instance, umbrellas are commonly made with this fabric, and taffeta fabric is also used to make certain forms of insulation. In addition, this substance is sometimes used to make handbags and the stuffing in sleeping bags, and during World War II, this fabric was commonly used to make parachutes.

Where Is Taffeta Fabric Produced?

Silk taffeta fabric was originally produced in Ancient Persia, but it is unclear how closely this fabric resembled modern taffeta. Over the years, production of this fabric spread to China and India, which remain the biggest producers of silk in the world.

While this fabric is still produced in the Middle East to some degree, factories in India have been the premier producers of taffeta fabric for centuries. This textile is also produced in Pakistan, and China, which is the leading producer of most types of textiles, also contains many factories that produce this type of fabric whether it is made from silk or a synthetic material.

Simple yet stunning taffeta gown

Simple yet stunning taffeta gown

Factories in India only started using mechanical looms to produce textiles in the 1990s, and while high-quality taffeta fabric was produced in China between 1970 and 1990, this country no longer produces the highest-quality forms of this fabric. Modern taffeta fabric was originally developed in France and Italy during the late 19th century, and it remains the case that the best types of this fabric are still produced in Western nations. Russia is also a relatively significant exporter of this textile product.

How Much Does Taffeta Fabric Cost?

The cost of this type of fabric varies depending on the material from which it is made and the taffeta fabric variant in question. For instance, silk is much more expensive than polyester, but most experts agree that silk taffeta is superior to synthetic forms of this substance.

While taffeta fabric is made with a variety of different types of synthetic textiles, most of these textiles are relatively equal in price. However, polyester fabric may be less expensive than cuprammonium rayon due to disparities between global production volumes.

What Different Types of Taffeta Fabric Are There?

There are quite a few different types of this fabric, and it's important to be familiar with the differences between each variety:

• Silk taffeta: Taffeta was originally made from silk, and many producers still use silk to make this fabric.

• Synthetic taffeta: In contemporary times, it's become increasingly common to find taffeta fabric that's made from synthetic materials like polyester or rayon.

• Yarn-dyed taffeta: This version of this textile is dyed before it is woven, which results in a crisp and stiff final product.

Black & Gold Check - Silk Taffeta Fabric

Black & Gold Check - Silk Taffeta Fabric

• Piece-dyed taffeta: This form of taffeta fabric is dyed after it is woven, and it is significantly softer than yarn-dyed variants.

• Paper taffeta: This type of fabric is made from extra-thin silk or polyester fibers, and the resulting finished textile is incredibly thin and crisp.

• Shot silk taffeta: To make this type of taffeta fabric, different colored threads are used for the weft and the warp, which are the two perpendicular threads that are used to weave textiles. The resulting fabric appears iridescent, and it displays different colors when viewed from different angles. While this fabric is sometimes made from polyester, silk is still the preferred material for shot silk taffeta. This type of fabric is also known as chiné or Pompadour taffeta.

• Antique taffeta: This fabric is very stiff, but it also contains soft lumps of yarn at regular intervals.

• Moire taffeta: This type of taffeta fabric has a rippling watermark pattern.

How Does Taffeta Fabric Impact the Environment?

The way that taffeta affects the environment varies depending on the fiber from which it is made. Out of the various substances that are used to make this fabric, silk is, by far, the most environmentally-friendly.

The only way in which silk production has a negative impact on the environment is through its destruction of living silkworms. While this might be an issue for animal rights organizations, most textile enthusiasts and environmental activists embrace silk's minimal environmental impact in comparison to the havoc that is wreaked by synthetic or semi-synthetic textile fibers.

Silkworms live out their entire lives on the surfaces of mulberry trees, and no pesticides or fertilizers are required to grow these types of trees. The silk production process does not require the use of any caustic chemicals, and in most cases, environmentally-friendly dyes are used to color this type of fabric.

In addition, silk is entirely biodegradable; once a silk garment is discarded, it will be reclaimed by the environment within a matter of years or decades. This attribute ensures consumers that their purchases of silk products will not substantially contribute to pollution.

Using taffeta fabric for the 1st time with real embroidery

Using taffeta fabric for the 1st time with real embroidery

Both polyester and rayon, however, are significantly detrimental to the environment in a number of ways. Polyester is derived from petroleum oil, which is a non-sustainable resource. There is only a certain amount of petroleum oil left in the world, and since this substance is also used to make a variety of plastics, fuels, and oils, it is often in high demand and short supply.

A variety of toxic chemicals are used during the polyester production process, and some of these chemicals may be released into the environment if they are not properly contained by manufacturing plants. In addition, polyester is not biodegradable; it's estimated that polyester garments will remain pollutants in the ecosystem for centuries or even millennia after they are discarded.

Cuprammonium rayon, which is the type of rayon most commonly used to make taffeta fabric, is somewhat better for the environment than other forms of rayon since it is produced using a closed-loop extraction process. However, solvents used to make cuprammonium rayon damage the environment when they are not disposed of properly. While rayon is technically biodegradable since it is made with tree cellulose, this product is semi-synthetic, which means that it is not as rapidly absorbed into the environment as fully organic fibers.

Taffeta Fabric Certifications Available

This type of fabric may be eligible for a wide variety of different forms of certification depending on the material from which it is made. When silk fabric is made within the United States, for instance, it may be eligible for U.S. Department of Agriculture (USDA) organic certification if it is made using sustainable and non-toxic standards. The European Union's organic product certification service may provide similar certification to silk products that are grown in Europe.

If taffeta is made from synthetic substances, such as polyester, it may be eligible for Global Recycle Standard (GRS) certification if it is made with 100 percent recycled materials. Otherwise, it is possible to ascertain the quality of polyester or rayon taffeta fabric product based on whether or not it is labeled as being in compliance with ISO 9001 standards. If an American-made textile has also been certified by the American National Standards Institute (ANSI), it is guaranteed to be high-quality.