A tech pack is a document containing all the technical information about your product. It’s an essential document for both designers and production teams when producing new collections, as it helps clearly communicate every little detail about what you are making, to your manufacturer.

Many designers, however, often overlook or rush through this document dismissing it as unimportant, leading to communication breakdowns further down the line and avoidable costly mistakes and delays. Read on to find out exactly why techpacks are so important.

What does a good tech pack include?

- Technical drawings, CAD, construction notes, dimensions and fit log: Annotated flat drawings showing a front and back view and close-ups of any design details such as packets, pleats, etc., seams, bartacks, stitching details and a table with all product dimensions and the size and placement of each component.

- Quantities & sizing: A table indicating the quantities you are looking for and the size split.

- Materials: Information on each key raw material that makes up your product, with name, colourways, composition, weight, finish, and a nominated supplier if you have one.

- Components: Information on each component that makes up your product – embroideries, prints, labels, buttons, tags, threads, trims, fastenings and embellishments.

- Sample and fit feedback

- Order details: Desired delivery date, bulk production delivery address and details on how you want your products packaged and packed.

Why is a tech pack important?

1. Reduces mistakes and improves communication

Tech packs make communication between you and your manufacturer easier and clearer, reducing misunderstandings and mistakes. A strong tech pack is even more important when manufacturing abroad, across time zones, language and cultural differences and are considered a universal system for enabling production.

You can ensure that the garment you have designed is made to your exact specification. Your clothing manufacturer will be able to use all the technical drawings, measurements and details of components that you provide to accurately replicate your design. In this way, it reduces the risk that a mistake will happen during sampling and bulk production.

2. Acts as a production manual

Usually, you have a single point of contact at a factory who looks after the entirety of your order; from designing, sourcing, sampling and production. However, during this process, your product passes through many different people and departments within the factory and they all need to be working from the same document or platform as each other. Revisions and details will inevitably get lost or misinterpreted if not all in the same document or platform, so your tech pack essentially becomes an instruction manual bringing clarity, consistency and cohesion throughout the production process.

3. Reduces lead times and avoids delays.

A design that comes with a detailed pack shortens sampling lead times, avoids mistakes and ultimately helps you bring your product to market quicker. It also helps the factory effectively plan the manpower and resources needed, and block out production capacity well ahead of time.

If you send a comprehensive tech pack along with a request for an initial quote, your manufacturer can break down your costs into materials, component and labour costs and will be able to cost more accurately and quickly, which means more control over cash flow. All of this information helps you work out margins and identify whether you need to make fundamental changes to your collection before you begin pattern making, sourcing and sampling.

4. Saves time with future collections

A tech pack can be referred back to at any time. When starting the next collection, slight changes to certain elements of your product are sufficient and tech packs can easily be reused.

What are the best tools for creating a Tech Pack?

Microsoft Excel and Adobe Illustrator are the most common programs used for creating tech packs. Although these are great tools that are easily customisable and quick for teams to learn, it’s not built with the unique and complex needs of fashion production and product development in mind. Although it may seem easier at first to create a tech pack in Adobe, Excel or Powerpoint, problems arise with these tools as the product evolves through the product development process; when edits are made, versions attached and sent via email.

What are the key challenges with current tools?

1. Harder for Collaboration: Tech Packs are collaborative documents, both your team and your manufacturers need to edit, comment or modify. This is not so easy to do on read-only attachments, .pdfs, or offline documents. Comments and changes need to be made in real-time.

2. Risk of making costly mistakes: Tech packs made using Excel or similar tools are either attached or uploaded to a platform like We Transfer and embedded as a link and sent via email. It increases the possibility of the files not being sent to the right individuals, or in some cases, the link expiring! This method also makes it easy to attach the wrong version, too many attachments being sent or a critical bit of sample feedback forgotten. These small human errors can be very costly.

3. Miscommunication: Manufacturers have to get used to the unique tech packs for every brand they produce for — it’s easier for them if there is a certain degree of standardization across all the tech packs they receive from every brand.

Digital tech packs are the future

Digital tech packs have similar functionality to those made on tools like Excel or Google Sheets, but because they are created, shared and modified in a cloud-based software used by both brands and manufacturers. Teams can create digital tech packs in minutes through the SupplyCompass Platform.

Top 5 benefits of digital tech packs

- Faster to create

- Intuitive to use

- Easy to share

- Real-time collaboration

- Single source of truth

Your business started with a vision. Now, it is time to get in touch with clothing manufacturers and let them do the magic that will turn your ideas into a saleable product. The reputation and success of your business will depend on how well this process is executed, so ensuring you prepare the specifications in advance will get you off on the right foot.

Once you find the right apparel manufacturer for your brand, open and concise communication is required to translate your ideas into wearable garments. So, what is the best way to share your vision?

It will come as no surprise that sending rough sketches to a manufacturer just won’t do the trick. If you already have some experience in the clothing industry or have done some basic research, you will probably have heard of a "tech pack" by now. If not, take a look at how this tool can benefit your fashion business. A tech pack is a link between your ideas, design, and final product. Think of it as a guidebook of your brand for garment manufacturers.

In this article, we will demystify tech packs and make sure you have the right knowledge and confidence to address this important stage of launching a clothing brand. A standardized form of communication between you and your clothing manufacturer is key to ensure efficient and qualitative garment production. The good news is that once you polish these technical specifications, the final result will not disappoint.

What Is a Tech Pack?

A tech pack is a comprehensive packet of design details that is provided to a pattern maker after you have gone through the process of designing a garment. This set of documents allows a fashion designer to maintain quality control over his or her idea as it is developed into a pattern that can be produced by a textile manufacturer.

Putting together this informative sheet is a crucial aspect of your design process since it includes information on the raw materials, size ranges, and trim details of your garment, and it also includes technical drawings and other information, such as artwork placement details, that will help a pattern maker create a pattern to your exact specifications.

Why Do I Need a Tech Pack?

A tech pack is one of the most crucial fashion business tools when you're in the process of taking your ideas through to the production stage. It is important to have a detailed tech pack on hand when you are engaging in a conversation with a manufacturer, and don’t be afraid to put down more detail than might seem necessary. After all, you don’t want to be financially responsible for any errors.

Creating a Tech Pack

Supplying your clothing manufacturer with the correct specifications leaves less room for misinterpretation. It’s important not to leave anything to chance, so creating a comprehensive tech pack will harmonize the production process.

Take a look at the key areas that a complete tech pack should cover and the details of how to complete each section:

- Sketches and descriptions

- Styleboard and inspiration

- Fabric placement and garment construction

- Color choices

- Materials list or bill of materials (BOM)

- Seam-to-seam measurements

Sounds like a lot of work, doesn’t it? Don’t get discouraged just yet. With our step-by-step instructions, you will overcome the initial confusion and create a transparent dialogue with your clothing manufacturer.

1. Sketches and Descriptions

Your tech pack should start with a black and white flat sketch that shows the front and back views of the garment. Make it as simple as possible, and do not use any color. You can also create digitized sketches with software such as Adobe Illustrator to create your images.

Further information: The Role of Computer-aided Design in the Tech Pack Template

2. Style Board and Inspiration

This section is a style board of your brand. Here, add the images and patterns that inspired you to create the original ideas. These can include textures, prints, cuts, and styles that represent your vision. You also might want to add some comments to ensure it is clear that your images are translatable to the manufacturer.

3. Fabric Placement and Garment Construction

This section highlights the desired assembly of the clothing, and it should include construction diagrams. Sketches of your clothing should be marked in relation to what type of material you want to be placed in certain areas including everything down to the small details such as label placement. For example, use stripes to indicate the use of one type of fabric and dots for another type. Label what each pattern corresponds to in a comprehensive key under the illustration.

Use as many arrows or notes as needed to get the message across, but when writing comments, always decrypt any abbreviations or acronyms you might have used. When it comes to garment assembly, it is vital to have clear codes for each type of print or fabric to avoid misinterpretation.

4. Color Choices

Identifying the specific colors that should be used is vital to get the look and style of the garment correct first time. You should include the color name, number (Pantone color or original number), and color swatch. You can also add print colorways if your design does not include solid colors.

5. Materials List or Bill of Materials (BOM)

Details regarding the fabrics for your designs should be included in the materials list or bill of materials (BOM). This highlights every aspect of your garment including the shell, lining, pockets, fasteners, and labels, and this list can be broken down into five sections as illustrated below:

- Placement: Where the material will be used or in what position it will be sewn into the garment.

- Comments: Detail any critical information about the use of the material.

- Material: Be sure to indicate fiber content, what material it is made of, and the identification numbers.

- Supplier: Identifying who is supplying the fabric.

- Colour Number: Experts say there are 150+ shades of grey, and this makes you appreciate the importance of mentioning the exact colors required for your design.

6. Seam-to-Seam Measurements

This is often classified as one of the most technical aspects of the tech pack, but your seam-to-seam measurements are critical to securing the right fit, style, and sizes for your garments. This section usually contains five columns and assists in producing the pattern and first fit sample.

- Point of Measure (POM): Each piece of a garment must fit with each other just right; otherwise the final product will not be assembled well. Note down the types of measurements that must be used for each part of the style.

- Description: Indicate how the measurements must be done. This part must be very specific as manufacturers must have clear information on how each point should be measured. HPS (high point of shoulder) will be the main starting point for most vertical measurements, and you must not forget to mention it in the description.

- Requested: You must have had an idea of the final size of your product. In this section, you specify the actual measurements. If you need help deciding, do not fill this part in, but instead, contact the clothing factory to assist you. You can always adjust the values after the first fit.

- Tolerance (+/-): This section indicates the most and least a measurement is allowed to be over or under the requested measurement. Production must stay within the range.

- Fit comments: Add any important notes to accompany the measurements provided.

How to Make a Professional Tech Pack

A tech pack is a tech pack, but the care you take in making this product development tool has a direct correlation with the overall success of your garment. If you provide your pattern maker with the bare minimum of information and other necessary components, you'll get the bare minimum of positive results for your efforts.

As you assemble your technical packet, keep the pattern maker's perspective in mind. The harder your packet is to sift through and read, the harder time your pattern maker will have with your project. On the other hand, if you present the necessary information in a streamlined manner, it will be easy for your pattern maker to get the gist of things and tackle the project in style.

To make your tech pack easier to understand, consider adding helpful features like a cover page that features information like your company name and a non-technical image of the intended final product. Provide a step-by-step breakdown of the details of the project, and include graded specs to make it as easy as possible to make a variety of pattern sizes from the information you provide.

Ideally, your tech pack should read something like an instruction manual. Your pattern cutter will, of course, interject his or her own expertise or else there would be no point in hiring a professional to do this work. However, the amount of guesswork involved in the process should be minimized to ensure that the garment you envision survives the pattern making process and ends up seeing the light of day.

Differences Between Tech Packs and Spec Sheets

If you've been in the design industry for a while, it's likely that you've heard the term "specification sheet" thrown around from time to time. While your spec sheet is another important tool in the process of making your design vision come to life, there are some important differences between tech packs and spec sheets that you should understand before moving forward.

Spec Sheet

A specification sheet is a single document that describes most of the important details regarding your project. It displays a flat drawing of your design accompanied by a technical drawing for the manufacturer.

This document should include all of the technical details required to make your garment, and a good spec sheet features measurements, material details, and any relevant information on accessories or prints.

Since your spec sheet will combine so much data in such a compact format, a single error in this document could cause serious headaches down the road. There isn't a lot of room to explain what you're going for with your spec sheet; it simply includes all of the raw details, and you'll rely on your tech pack to flesh things out.

Tech Pack

Your tech pack will include your spec sheet, but it will also include so much more. In addition to the spec sheet, this document will also feature a professional cover sheet and a grading sheet.

Your grading sheet will include information on the garment's original measurements, but it will also offer information on how to scale these measurements to make custom or standard sizes. A tech pack gives a designer or a fashion brand more room to explain all of the details that a pattern maker or manufacturer might need to create a final apparel product, but it's still incredibly important to get all of the details of this document right if you want to end up with a product that's anything like the design you've come up with.

Bringing Your Fashion Brand to Life

A tech pack contains a lot of information that can sometimes feel overwhelming. If you require assistance, asking for advice from your clothing manufacturer or a technical designer will assist you in turning your ideas into workable specifications. Before you send your tech pack to the clothing producer, make sure you review the information to the degree that you feel confident in your brand blueprint. Taking this step will allow you to avoid any issues or miscommunications.

Should You Hire a Professional or Make a Tech Pack Yourself?

Making a tech pack on your own is no simple process. You'll need to have skills in Excel and Word, and you'll also need to know how to put together finished documents that can be printed out by the various product developers who you'll work with as your apparel dream takes flight.

If you think you have what it takes to make a tech pack on your own, you can save some money by taking this path, but if you make any mistakes during the process, there may be serious problems with your final product. At the very least, take advantage of some of the free tools that are at your disposal online that can help you formulate a tech pack that makes sense to your pattern maker and manufacturer.

As you make a decision on how to proceed, keep in mind that working with a professional tech pack expert isn't necessarily a surefire way to make sure that your apparel ends up looking its best. Professional tech pack creators aren't inherent experts on your design; you'll need to explain every nitty-gritty detail of your plans for your garment to make sure that the person you hire produces the results you're looking for. In the end, you may find it to be easier to take care of this process yourself.

The DIY Tech Pack Process

If you decide to make a technical packet on your own, you'll need to start by arranging all of the pertinent details regarding your garment. First, you'll need to make a detailed sketch of your garment that aligns with all of the measurements that you expect the final product to have. You'll use this sketch to make your cover sheet, and you'll use it again to make a more detailed spec sheet.

You'll also need to spend some time with a calculator to ensure that you get all of the measurements in your grading sheet right. Make sure to also use the generic names for the materials you want to use with your garment to give your manufacturer a good idea of development costs, and integrate considerations like seam allowances and points of measurements to make the process of constructing your garment as easy as possible.

Create a Tech Pack with Sewport

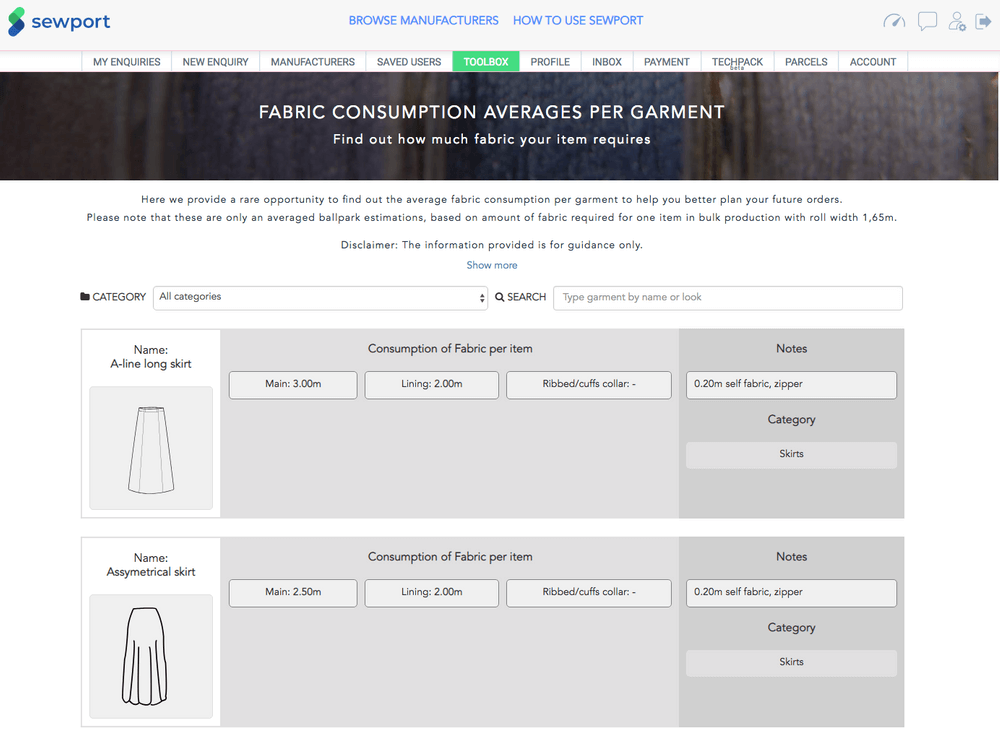

Sewport’s innovative platform has a variety of tools and services to help you create your own tech pack to share with clothing manufacturers. This comprehensive and easy-to-use feature helps to detail the specifications (as mentioned above) to easily communicate your ideas to suppliers. There is also a range of other features too, including Sewport’s handy toolbox, which provides guides on garment types and fabric consumption.

It’s free to sign up and take advantage of these tools. Just create an account here to get started.

Join the Sewport community

You must be exhausted by now. The good news is that you almost crossed the finish line, and you are ready to produce your first sample!

The Sewport team hopes that this breakdown of the tech pack convinced you that it is a worthwhile and achievable task. Whether you decide to create a tech pack with our handy tools or hire a professional, it is always useful to understand what the final tech pack must contain to make the production process simple and straightforward.