| Fabric name | Banana fabric |

| Fabric also known as | Banana fiber, banana silk, musa fiber |

| Fabric composition | Yarn spun from strands derived from the soft inner lining or coarser outer lining of banana peels |

| Fabric possible thread count variations | Upward of 1,000 |

| Fabric breathability | High |

| Moisture-wicking abilities | High |

| Heat retention abilities | Low |

| Stretchability (give) | Low |

| Prone to pilling/bubbling | Low |

| Country where fabric was first produced | Unknown |

| Biggest exporting/producing country today | India |

| Recommended washing temperatures | Cold or warm - Theoretically, banana silk should be able to withstand hot water, but it is delicate |

| Commonly used in | Light clothing, tropical clothing, shawls, cardigans, blouses, slacks, pants, skirts, hats, scarves, ropes, mats, etc. |

15476-539 Banana by Duralee

15476-539 Banana by Duralee

What is banana fabric?

Just as you’d expect, banana fabric is fabric made from bananas. Not the mushy, fruity part, though—the outer and inner peels, which are both quite fibrous.

Just like hemp, which produces a flowering and a stem section, banana stems and peels yield fibers that can be made into textile products. This practice has actually been done for many centuries, but it’s only recently that the world of Western fashion has caught on to the textile potential of the common banana.

Green Bananas Fabric

Green Bananas Fabric

Banana fabric in history

It’s likely that the Philippines was the first place where banana peels and stems were made into fiber. This island chain is home to countless banana trees, and the industrious indigenous peoples of the area have made banana fabric for millennia.

A few other Asian cultures historically experimented with banana-based fibers, but the concept never caught on quite like it did in the Philippines. The closest example would be India, which has gradually supplanted the Philippines as the world’s banana fiber hub.

As Western interaction with Southeast Asia increased, textile manufacturers from Britain and the United States became curious about the potential of banana fiber. Since then, Western fashion has occasionally flirted with this exotic fabric, but basic drawbacks make it less commercially viable than common alternatives.

Pale Banana Yellow Silk Crepe de Chine

Pale Banana Yellow Silk Crepe de Chine

Attributes of banana fiber

- The inner layer is soft like silk

- The outer layer is rough like burlap or cotton

- The silky interior fiber is very delicate

- At the same time, it is often more expensive to produce than silk

- Since silk is already one of the planet’s most sustainable fibers, banana fiber is not in high demand worldwide

Banana fabric today

Very little banana fiber is still produced in the Philippines. Instead, it’s mainly made in India, and many manufacturers in this country focus extensively on sustainable and organic practices. While there’s some opportunity for unsafe cultivation practices during the banana growth cycle, it’s unlikely that the presence of trace amounts of pesticides or fertilizers will significantly affect the end user.

How is banana fabric made?

There are a few steps in the banana fabric production process:

Separation

First, the fibers in banana peels and stems must be separated from the non-usable components. Various techniques may be used to achieve this end result, including retting, which involves the soaking of banana peels in water or a chemical substance to soften and separate the components. The unusable parts of the banana peel may also be sliced off, but this approach is more labor-intensive.

Bunching and drying

Once the separated fibers are acquired, they are bunched together and dried. At this stage, the inner and outer fibers are usually kept together since it’s hard to separate them when wet.

Simple Sage Organic Banana Fibre

Simple Sage Organic Banana Fibre

Dividing into groups

Once dry, the fibers are separated into groups based on quality. The “A” group consists of the best-of-the-best, and it is used for silk-alternative applications. Some manufacturers may only have two groups, but others might produce a variety of different banana fiber grades.

Spinning and weaving

The separated fibers are then spun into yarn. The yarn is treated and dyed, and it is woven into garments, accessories, decor items, or industrial products.

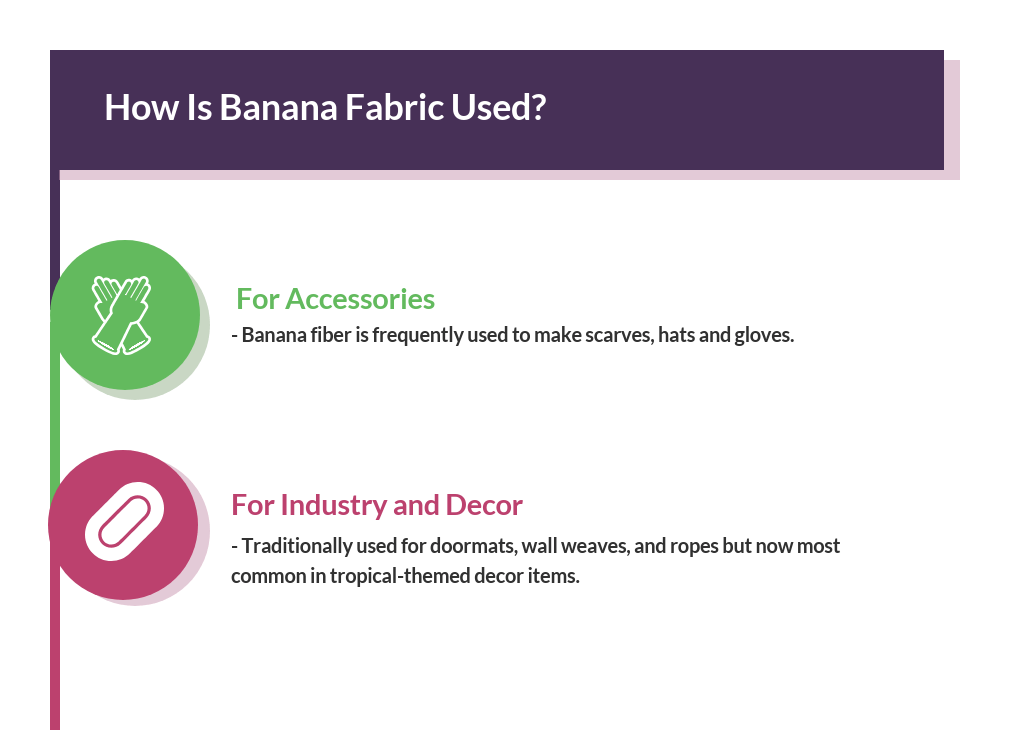

How is banana fabric used?

Banana fiber is used very differently depending on whether it is made with the inner or outer peel and stem lining. The inner lining is so soft that it’s been likened to silk, and much like silk, banana fabric is highly temperamental and delicate. Banana fiber is used as an alternative for any garment commonly made from silk, so that includes blouses, shirts, negligees, lingerie, slips, gowns, robes, eveningwear, etc.

Use in accessories

When it comes to accessories, expect to see banana fiber used more frequently to make scarves, hats, and gloves as sustainable, organic products become increasingly popular.

Textile Spotlight Banana Fabric

Textile Spotlight Banana Fabric

Use in industry and decor

Traditionally, a lack of technological sophistication limited banana fiber use to rough applications like doormats, wall weaves, and ropes. In some indigenous communities, banana fiber is still used for these ancestral purposes, but applications of this fiber outside the realm of wearable products are usually limited to tropical-themed decor items.

Where is banana fabric produced?

At 28.4 million tonnes per year, India is the world’s largest producer of bananas, so it only makes sense that this Asian country is also the biggest producer of banana fiber. The Philippines is no longer a banana fiber production hub, but this fabric is still made for traditional purposes in small quantities in this island chain nation. Almost all banana fiber that reaches Western markets was manufactured in India.

How much does banana fabric cost?

High-quality, inner-lining banana fiber is generally quite expensive. It’s tricky to produce, and it has the same qualities as silk, which means this lustrous fabric has a lot of market value.

Rougher, outer-lining fabric is usually cheaper. You can also often save by choosing conventional over organic fabric, but remember that you’re exposing yourself to potential toxin contamination if you go that route.

What different types of banana fabric are there?

There are only two main types of banana fiber, but there are four terms you should be familiar with:

1. Inner-peel banana fiber

This type of banana fabric is very soft like silk. It is relatively expensive to produce, and it is reasonably delicate.

Tomorrowland Banana Pants

Tomorrowland Banana Pants

2. Outer-peel banana fiber

Used for centuries in industrial applications, this rough, coarse fiber is perfect for mats, ropes, and in some cases, outerwear and thick garments.

3. Banana cotton

High-grade outer-peel banana fiber is sometimes called banana cotton. Its texture is similar to cotton, and the two fabrics share many other attributes as well.

TA5323.14 Vine Cord Banana by Kravet Design

TA5323.14 Vine Cord Banana by Kravet Design

4. Banana silk

“Banana silk” is another term for inner-peel banana fiber.

How does banana fabric impact the environment?

Banana fiber production has a negligible impact on the environment. Even among the natural fibers, banana fabric is in a special category in terms of sustainability. That’s because this fabric is derived from what would otherwise be a waste product; banana peels are discarded anyway when banana fruit is used, so why not turn them into clothing?

With that said, there’s no guarantee that banana production is always done sustainably and with the environment in mind. While it has come a long way under Modi’s leadership, India is still a far cry from a first-world country, which means that synthetic pesticide use is rampant in this poverty-stricken nation. When you’re struggling just to survive, you’ll do anything to make money, and the consequences of unsustainable agricultural practices seem very far away.

If done properly, banana fabric production can be in perfect harmony with the environment. We encourage banana producers around the world to look into offering their peels to textile manufacturers, and we’re sure the global trend toward sustainability will gradually uplift banana fiber to its rightful place in the natural fabric pantheon.

Banana fabric certifications available

At present, certification has very little relevancy in the banana fiber industry since it is a niche product. As banana fiber becomes more popular, it’s possible that specific certifications may arise catering to this emerging industry.

You’ll need to content yourself with the knowledge that your bananas were grown organically for now. The USDA provides organic certification for bananas even if it doesn’t offer certification for banana fiber, and the end result is the same. You want safe, sustainable banana fiber, and going organic is the way to get it.