| Fabric name | Batiste |

| Fabric also known as | Lawn cloth, cotton batiste, batiste de soie, toile de baptiste, cambric |

| Fabric composition | Cotton, synthetic, or semi-synthetic fibers |

| Fabric possible thread count variations | 150-350 |

| Fabric breathability | High |

| Moisture-wicking abilities | Medium |

| Heat retention abilities | Low |

| Stretchability (give) | Medium |

| Prone to pilling/bubbling | Depends on the fabric used |

| Country where fabric was first produced | France |

| Biggest exporting/producing country today | India or China |

| Recommended washing temperatures | Cold or cool |

| Commonly used in | Dresses, blouses, dressing gowns, bathrobes, pyjamas, fabric lining, handkerchiefs, lingerie, sheets, bedding, drapes |

Rayon Batiste Solid Charcoal

Rayon Batiste Solid Charcoal

What is batiste fabric?

Batiste is a semi-sheer plain-weave fabric that textile manufacturers commonly use to make lightweight garments, lingerie, and bedding. This type of fabric is usually made with cotton, but some manufacturers also use polyester or lyocell. Prized for its lightweight and semi-transparent attributes, batiste is a luxury fabric despite being reasonably inexpensive.

While reasonably crisp, batiste is not as crisp as other semi-sheer cotton weaves such as organdy. This fabric has high tensile strength and durability even though it is not as heavy-duty as alternative plain-weave textiles like lawn cloth.

Almost every type of batiste is plain-weave, but textile manufacturers can also produce this fabric using a satin weave to provide it with a shinier finish. Most types of batiste fabric contain mercerized cotton, which is cotton yarn that textile producers have exposed to caustic alkali to produce a shiny effect.

Batiste Shadow

Batiste Shadow

History of batiste

Historians consider “batiste” to be a synonym of “cambric,” which was originally a linen fabric named after the Flemish city Kambryk, now known as Cambrai. Throughout the Middle Ages, an area in northwestern Europe known as the Low Countries supplied the continent with most of its linen textiles, and cambric or batiste remained one of the most popular Low Countries textile exports for centuries.

Some sources indicate that batiste fabric takes its name from a famous 14th-century French weaver named Jean Baptiste, but there are no historical records to verify this claim. There is, however, an etymological trail that traces the fabric name “baptiste” back to the Picard dialect word “batiche,” which historians believe has been used since the early 1400s.

Throughout the 15th and 16th centuries, terms like “thoile batiche” and “toile de baptiste” were used to refer to a lightweight linen fabric that greatly resembles modern batiste. By the early 1900s, baptiste was widely known as a French synonym for cambric, and this textile remained a popular fabric for women’s clothing and handkerchiefs. At this point, however, baptiste had diverged dramatically from its original form as a 100%-linen fabric.

![SNOW WHITE BATISTE FABRIC 118 BY THE YARD [BATISITE-WHITE]](https://s3.eu-west-2.amazonaws.com/files.sewport.com/fabrics-directory/what-is-batiste-fabric-properties-how-its-made-and-where/_SNOW%20WHITE%20BATISTE%20FABRIC%20118%20BY%20THE%20YARD%20%5BBATISITE-WHITE%5D%20.jpg) SNOW WHITE BATISTE FABRIC 118 BY THE YARD [BATISITE-WHITE]

SNOW WHITE BATISTE FABRIC 118 BY THE YARD [BATISITE-WHITE]

Batiste today

During the 1600s, the British and Dutch started importing cotton into Europe, and while this textile fiber remained unpopular for some time largely due to pushback from local linen manufacturers, cotton imports from India gradually became an integral part of daily European life. Today, batiste is almost exclusively associated with cotton, and it is remarkably rare to find batiste garments consisting entirely of linen.

Despite the considerable changes it has undergone throughout the centuries, batiste remains a reasonably popular plain-weave textile. More lightweight than lawn cloth but not as sheer as organza, batiste occupies a seemingly permanent niche among semi-sheer cotton weaves. Frequently festooned with lacy edges, batiste retains an association with upper-class luxury.

How is batiste fabric made?

Batiste fabric almost always contains cotton fibers, but in some cases, textile manufacturers might mix cotton with linen to make batiste. It’s also becoming more common to find batiste fabrics featuring polyester or semi-synthetic fabrics like lyocell, which may be cheaper or, in the case of lyocell, softer than cotton or linen.

Linen is derived from the fibers of the flax plant, and cotton is derived from fluffy fibers that surround cotton seeds called bolls. Textile manufacturers make polyester fibers using petrochemicals, and lyocell is made by exposing wood pulp to a variety of caustic chemicals.

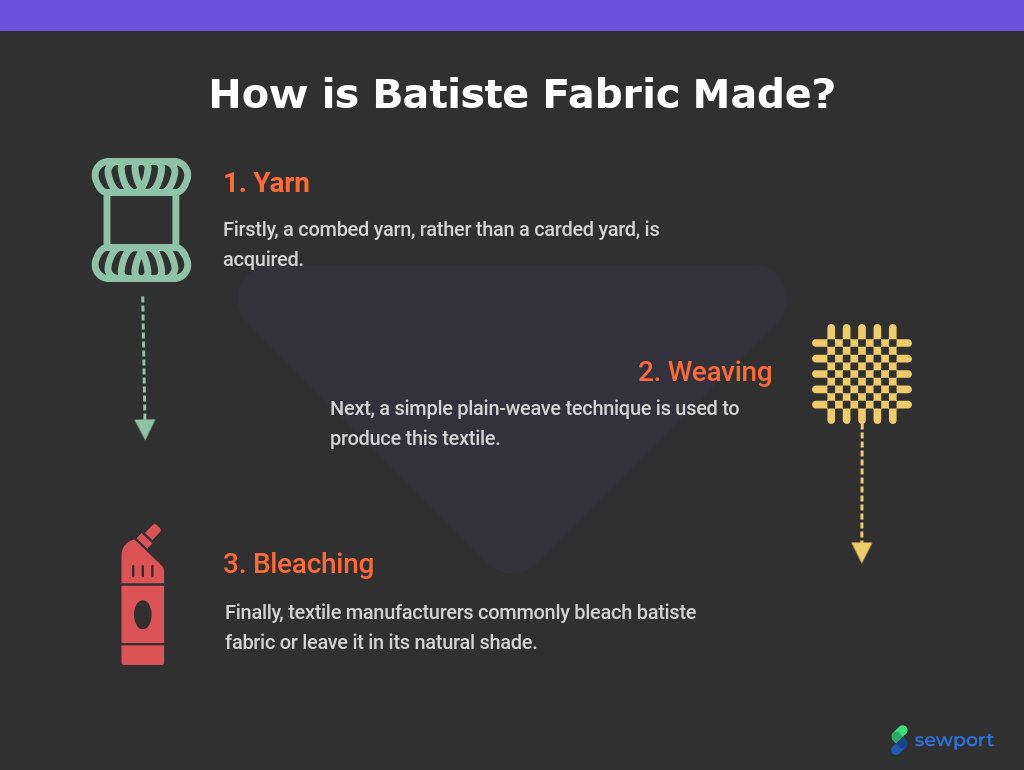

Since batiste is expected to be a soft, fine fabric, textile manufacturers usually use combed yarn to produce this textile. As opposed to carded yarn, combed yarn is softer and more uniform along its length. Textile manufacturers may mercerize the cotton they use for batiste production to make it shinier and softer.

Once textile manufacturers have acquired the type or types of yarn they intend to use to make batiste fabric, they use a simple plain-weave technique to produce this textile. Plain-weave consists of overlapping warp and weft threads, and it creates a uniform, criss-crossing pattern.

While it is common to dye or apply prints to lawn cloth and other fabrics similar to batiste, textile manufacturers more commonly bleach batiste fabric or leave it in its natural shade. White and off-white batiste fabrics are the most common, and dyed batiste is rarer.

How is batiste fabric used?

Throughout the Middle Ages and until the Victorian era, batiste was a fabric of choice for ladies’ garments, handkerchiefs, and linings for men’s coats and jackets. Due to its sheer softness, average consumers and connoisseurs alike considered this fabric to be a serious contender with silk. Even today, some fabric experts have trouble telling high-quality batiste and silk apart due to their highly similar properties.

These days, batiste is less of a mainstream fabric, and it is mostly relegated to niche uses. Certain subtypes of batiste, for instance, are commonly used in lingerie, hearkening back to the use of this fabric in corsets in earlier eras. Batiste is also a popular material for duvet covers, sheets, and other forms of bedding, and while highly translucent, this fabric makes for very attractive drapes.

Apparel manufacturers also use batiste to make classy yet casual clothing designed to be worn at home. From pyjamas to dressing gowns and bathrobes, batiste is a lightweight, moisture-wicking, and overall comfortable fabric that’s perfect for wearing at home while remaining aesthetically pleasing.

It’s also reasonably common to use batiste to make lightweight spring and summer garments. While this fabric isn’t heavy enough to insulate against inclement weather, it’s relatively common to find batiste sundresses, blouses, and skirts.

Where is batiste fabric produced?

Since batiste can contain a variety of different textile materials, the producer of the material or materials included in a batiste garment may vary. India, for instance, is currently the world’s preeminent producer of cotton, but textile manufacturers in this country commonly ship their raw cotton or cotton yarn to China for finishing.

China holds the distinction of being the world’s largest producer of finished textile products, and this country is also the biggest exporter of synthetic and semi-synthetic textile materials. Therefore, a given piece of batiste fabric is more likely to have been crafted in China than any other nation. However, a variety of major economies, including India, have recently become far less reliant on Chinese goods, so China’s status as the world’s biggest batiste producer may be in jeopardy.

How much does batiste fabric cost?

The cost per yard of batiste fabric is generally comparable to other types of cotton with similar thread counts. Some forms of batiste fabric, however, may feature adornments like lace or unusual weave patterns, and when customized, this fabric fetches a higher price. Batiste fabric made with polyester or lyocell may be less expensive than genuine cotton batiste, but these synthetic materials offer reduced quality.

What different types of batiste fabric are there?

Batiste has subtypes that you should familiarize yourself with, and there are also a few similar fabrics that are easy to confuse with batiste. Learn the variations of this lightweight and luxurious fabric:

1. Batiste de soie

Batiste de soie is a delicate form of batiste that textile manufacturers generally use to make lingerie. This type of batiste is more transparent and has a higher thread count compared to conventional batiste, and it is more likely to be adorned with lace and other add-ons.

2. Cambric

Most fabric experts consider cambric to simply be another name for batiste since these two textile products are practically indistinguishable. The fabric that came to be known as “batiste” in France went under the name of “cambric” in the British Isles.

3. Lawn cloth

Today, lawn cloth is all the rage throughout Pakistan and India as the primary material for salwar kameez or “lawn suits.” Named for the French city of Laon, this fabric is slightly heavier and more durable than batiste while remaining reasonably lightweight. Textile manufacturers commonly print lawn cloth with bright, ornate prints.

Hanes 118 Inch Cream Batiste Fabric

Hanes 118 Inch Cream Batiste Fabric

4. Organdy

This ultra-thin and remarkably crisp cotton fabric is woven similarly to batiste. Organdy is, however, far more translucent than batiste fabric, and it has the crispest hand of any cotton textile.

5. Voile

Like batiste, voile is a plain-weave cotton fabric. However, voile is nearly as transparent and organdy, and it usually has a lower thread count than batiste. Compared to organdy, voile has a slightly softer hand.

How does batiste fabric impact the environment?

The environmental impact of batiste varies depending on the types of fabric fibers it contains. In the past, textile manufacturers primarily used cotton to make batiste fabric, but the recent surge in popularity of polyester and especially lyocell batiste makes it necessary to take these fabrics into account as well.

Dotted Swiss Cotton Batiste Fabric - Black

Dotted Swiss Cotton Batiste Fabric - Black

Cotton has the potential to have a neutral impact on the environment, but the environmental impact of this substance is almost always at least somewhat negative. While it is a natural, plant-based fiber, cotton is susceptible to pests and receptive to fertilizers, incentivizing cotton producers to use agrochemicals in the cultivation of this crop.

Monocropping is also lamentably common in cotton production, and since the majority of the world’s cotton is grown in India and China, worker exploitation and the resulting environmental impact of poverty is also a major problem within the cotton industry. However, cotton is biodegradable, and it is possible to grow cotton organically without using any harmful agrochemicals.

While lyocell biodegrades slowly, polyester does not break down at all when subjected to normal environmental conditions. Instead, this petrochemical-derived fiber has the potential to pollute ecosystems after it is discarded, and both lyocell and polyester release dangerous microfibers into the water supply. The lyocell production process is slightly more environmentally friendly than polyester production, but it still involves the use of amine oxide, chlorine bleach, and other toxic chemicals.

Batiste fabric certifications available

Organically grown cotton batiste may be eligible for certification by the OEKO TEX, both of which are widely respected as reputable certifiers of organic textiles. OEKO TEX also certify fabrics made with recycled synthetic fibers, and the Global Recycling Standard (GRS) specifically certifies recycled synthetic textiles.

Batiste made with cotton grown in the United States or the European Union may be eligible for USDA or European Commission organic certification respectively. Cotton batiste made with pima cotton cultivated in the United States may also be eligible for SUPIMA licensing.