| Fabric name | COOLMAX |

| Fabric also known as | Moisture-wicking polyester |

| Fabric composition | Specially designed polyester fibers |

| Fabric possible thread count variations | 200-400 |

| Fabric breathability | High |

| Moisture-wicking abilities | High |

| Heat retention abilities | Low |

| Stretchability (give) | Medium |

| Prone to pilling/bubbling | Low |

| Country where fabric was first produced | United States |

| Biggest exporting/producing country today | United States or China |

| Recommended washing temperatures | Machine wash cool or cold |

| Commonly used in | Bed sheets, socks, T-shirts, face masks, bras, shorts, jeans, activewear, cargo pants, gloves, sleeping bag liners, sweaters, polo shirts, button-ups, cycling pads, saddle pads |

Xpril Men's 2 Tone Pattern Coolmax Fabric Short Sleeve Polo T-Shirt

Xpril Men's 2 Tone Pattern Coolmax Fabric Short Sleeve Polo T-Shirt

What is COOLMAX fabric?

COOLMAX is a specially engineered type of polyester exclusively produced by Invista, an American textile corporation. This polyester fabric consists of fibers that are carefully engineered to wick moisture and allow the passage of heat. COOLMAX fabric has a variety of potential applications, and it is a popular material for socks, jeans, and other types of apparel. While there are other fabrics with similar attributes to this engineered textile, COOLMAX is the sole trademark of Invista.

History of COOLMAX

Invista was originally a subsidiary of the DuPont Corporation, which has been responsible for the most important breakthroughs in synthetic textile engineering for the past century. In 2003, the direct predecessor to Invista, DuPont Textiles & Interiors, broke away from its parent corporation to become an independent company. Today, Invista is the sole trademark holder of COOLMAX, and this corporation no longer has any business ties with DuPont.

Mark Todd Mens Coolmax Grip Breeches

Mark Todd Mens Coolmax Grip Breeches

The story of COOLMAX begins in 1986 when DuPont textile engineers successfully developed a new type of polyester yarn that transferred both heat and moisture away from the body due to its unique shape. It wasn’t until 1998, however, that key members of the DuPont Textiles & Interiors team patented this new fabric under the name COOLMAX, and within five short years, this branch of the DuPont Corporation had reorganized into Invista largely to protect the highly valuable intellectual property that the COOLMAX brand had rapidly become.

Early in the history of COOLMAX marketing, DuPont and Invista executives envisioned this novel fabric as a direct competitor of merino wool due to its moisture-wicking and quick-drying properties. Consisting of oval polyester fibers with grooves running along their surface, the physical structure of COOLMAX fibers inherently encourages the passage of moisture away from the skin and onto the surface of the fabric for rapid evaporation.

Consumers quickly recognized COOLMAX as a lightweight, durable alternative to wool, and COOLMAX socks became commonplace during the 2000-2010 era. Now a subsidiary of Koch Industries, Invista’s production of COOLMAX fibers has benefited from its new parent corporation’s widespread network of factories in the United States, Canada, China, and elsewhere.

COOLMAX today

COOLMAX remains a relatively popular fabric for socks, T-shirts, sweaters, and a variety of other applications. Due to the recent pushback against synthetic textiles, COOLMAX has lost a reasonable degree of popularity.

Unlike plain polyester or other basic synthetic textiles, however, COOLMAX has unique physical attributes that cannot be replicated with other fabrics. Therefore, it is likely that COOLMAX fabric will remain popular within certain niche textile production categories for the foreseeable future regardless of which direction consumer sentiment regarding synthetic fabrics may swing.

How is COOLMAX fabric made?

COOLMAX fabric is identical to other forms of polyester in most ways aside from the notable exception of the shape of its fibers. Therefore, the COOLMAX production process mainly follows the steps used to produce other types of polyester fibers. This process is divided into four major stages:

1. Polymerization

Polyester fibers consist of substances derived from coal and petroleum. During the polymerization process, textile manufacturers combine dimethyl terephthalate and ethylene glycol to create a clear, molten polymer substance. Upon cooling, the newly formed polyester takes on the form of long, thin ribbons. Once dry, these ribbons are chipped into small pieces.

2. Proprietary melt spinning process

The small chips of polyester are once again melted and placed in a spinneret, which is a simple device similar to a showerhead that contains dozens of tiny holes. Most types of polyester production involve spinnerets with round holes, but to produce COOLMAX, Invista uses spinnerets with proprietary oblong holes that result in distinctively shaped fibers.

Llamaste 6-Inch Coolmax Socks

Llamaste 6-Inch Coolmax Socks

3. Drawing

Once cool, Invista employees stretch or “draw” COOLMAX fibers to increase their usable length. Stretching also increases the durability of COOLMAX fibers. Next, COOLMAX producers wind these drawn fibers onto bobbins for transportation or storage.

4. Weaving

Textile manufacturers can now use the stretched and wound COOLMAX fibers to weave fabric. In most cases, COOLMAX garments feature plain weaves, but they may also be knit or feature twill weaves.

How is COOLMAX fabric used?

COOLMAX fabric is a popular textile for various apparel items, but this unique type of polyester is also relatively popular within niche homewares and sporting goods categories:

Homewares

Some textile manufacturers use COOLMAX fabric to make bed sheets. Designed for warm climates, these bed sheets wick moisture and keep sleepers cool and dry. Most COOLMAX sheet sets also come with matching pillowcases.

Apparel

Socks are the most common apparel application for COOLMAX. This unique polyester fiber wicks sweat away from feet, reducing the likelihood of moisture-related podiatric conditions like athlete’s foot.

COOLMAX is also reasonably popular for T-shirts and polo shirts, and in some cases, jeans manufacturers combine this fiber with cotton to produce moisture-wicking denim. Some bras feature COOLMAX for enhanced breathability, and despite not being very stretchy, many activewear garments also feature COOLMAX fibers.

GRAMICCI COOLMAX KNIT SWEATER - CHARCOAL

GRAMICCI COOLMAX KNIT SWEATER - CHARCOAL

Sporting goods

Due to its lack of heat retention and high breathability, COOLMAX is a popular fabric for the pads on bicycle seats, which are called cycling pads. While less popular in terms of the sheer number of units sold, COOLMAX is also commonly used to make saddle pads, which cushion equestrian saddles.

Sleeping bag liners, which make sleeping bags more insulative and comfortable, commonly feature COOLMAX since this fabric moves moisture away from the sleeper’s body. COOLMAX is also a desirable fabric for cycling gloves and other types of sporting gloves.

Where is COOLMAX fabric produced?

Invista is the world’s sole supplier of COOLMAX fabric, and this company has manufacturing facilities all over the globe. The majority of COOLMAX production appears to take place at this company’s La Porte, Texas plant, and Invista also recently made an agreement to invest in a massive manufacturing facility in Shanghai. Invista’s corporate headquarters are in Wichita, Kansas.

How much does COOLMAX fabric cost?

COOLMAX fabric is generally priced slightly higher than other polyester fabrics. While the COOLMAX production process does not differ significantly from processes used to make other polyester textiles, the unique intellectual property that provides COOLMAX with its desirable moisture-wicking properties drives the price of this fabric upward. At the same time, COOLMAX fabric is usually less expensive than merino wool, cementing this synthetic textile’s status as a direct wool competitor.

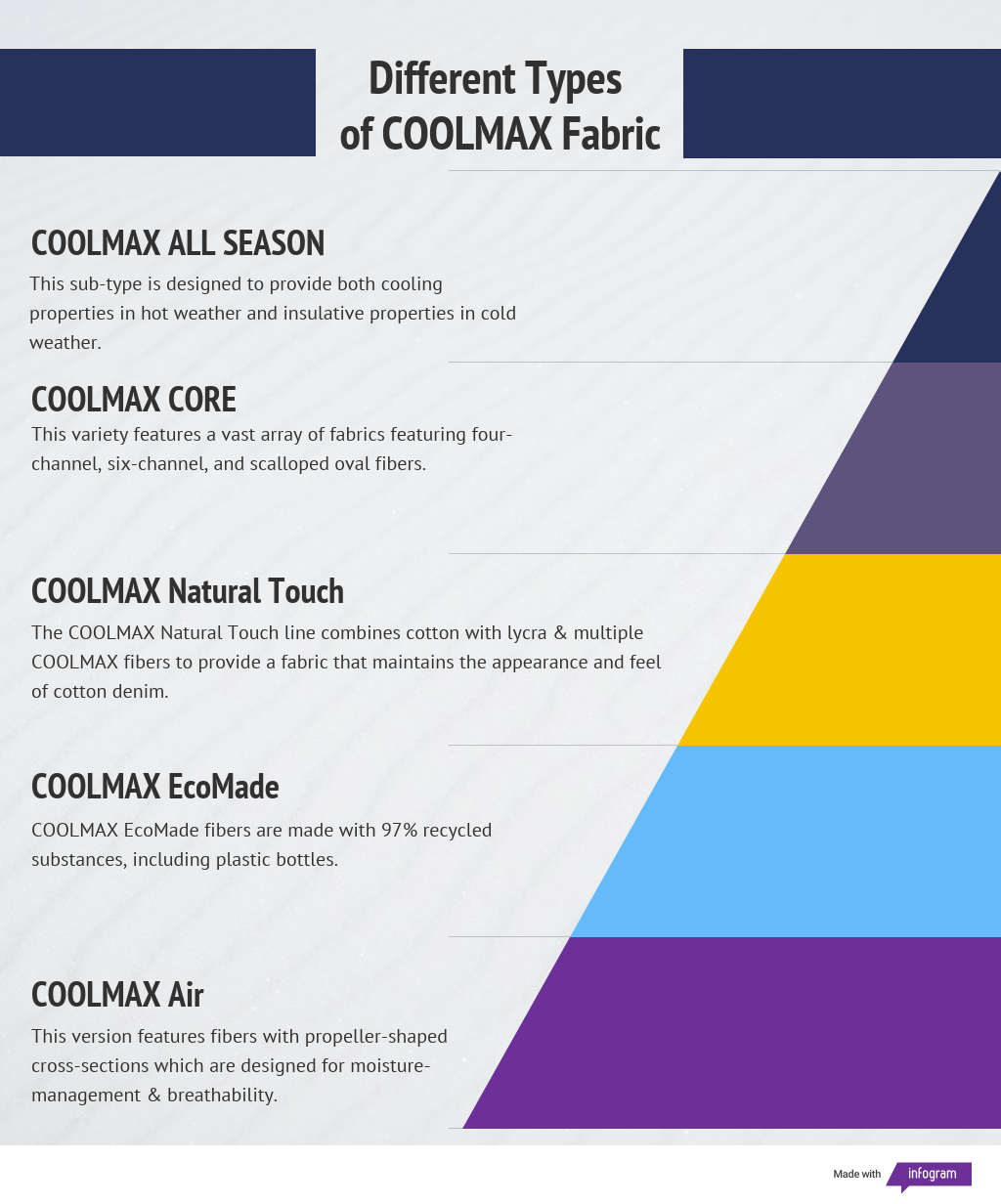

What different types of COOLMAX fabric are there?

Currently, Invista makes five distinct fabrics under the COOLMAX brand:

1. COOLMAX ALL SEASON

Invista designs this COOLMAX sub-type to provide both cooling properties in hot weather and insulative properties in cold weather. There are more than two dozen products within this category, and they feature a mix of scalloped oval, hollow, “C”, and “Y” shaped fibers.

2. COOLMAX CORE

As the original COOLMAX product line, the CORE line features a vast array of fabrics featuring four-channel, six-channel, and scalloped oval fibers. In contrast with ALL SEASON fibers, the products in the CORE line do not provide insulative properties in addition to cooling properties.

3. COOLMAX Natural Touch

Designed primarily for denim applications, the COOLMAX Natural Touch line combines cotton with lycra, multifilament COOLMAX fiber, and staple COOLMAX fiber to provide impressive moisture-wicking properties while maintaining the appearance and feel of cotton denim. The fibers in this line feature the distinctive COOLMAX scalloped oval shape.

COOLMAX® Fresh Fabric

COOLMAX® Fresh Fabric

4. COOLMAX EcoMade

Designed to capture rising consumer sentiment in favor of sustainable apparel, COOLMAX EcoMade fibers are made with 97% recycled substances, including plastic bottles. This new addition to the COOLMAX line is designed primarily for denim.

5. COOLMAX Air

The new COOLMAX Air line features fibers with propeller-shaped cross-sections. According to Invista, this unique shape provides “superior moisture management, breathability, and quick dry time.” COOLMAX currently offers five products within this line.

How does COOLMAX fabric impact the environment?

The measures Invista has taken to produce COOLMAX EcoMade fibers somewhat mitigate the environmental impact of this polyester fiber, but the remaining four products within the COOLMAX line have a decidedly negative impact on the environment. The production of COOLMAX fibers involves formaldehyde, which is a potent neurotoxin. Additionally, all types of polyester are unsustainable since they are made using fossil fuels.

While in use, COOLMAX fabrics contribute to microfiber pollution, and polyester fabrics like COOLMAX do not biodegrade when discarded. While COOLMAX EcoMade fibers address the issue of fossil fuel use in polyester production and initially reduce plastic pollution, these fibers are still made using formaldehyde, they contribute to microfiber pollution, and they inevitably contribute to plastic pollution when discarded.

COOLMAX fabric certifications available

Since Invista is the sole trademark holder and producer of COOLMAX fabric, this type of fabric is not eligible for third-party certification. Instead, Invista provides certifying materials to fabric producers who use COOLMAX fibers to make textile products. After testing at an Invista facility, textile manufacturers using COOLMAX fibers are eligible for notices of approval from Invista and are issued COOLMAX hang tags that they can attach to garments and other products intended for retail sale.