| Fabric name | Soy fabric |

| Fabric also known as | Vegetable cashmere, vegan cashmere, soy silk, soy protein fiber |

| Fabric composition | Fibers derived from byproducts of the soy industry |

| Fabric possible thread count variations | 100-500 |

| Fabric breathability | High |

| Moisture-wicking abilities | Medium |

| Heat retention abilities | Low |

| Stretchability (give) | High |

| Prone to pilling/bubbling | High |

| Country where fabric was first produced | United States |

| Biggest exporting/producing country today | United States or China |

| Recommended washing temperatures | Machine wash cool or warm |

| Commonly used in | Upholstery, dresses, tank tops, skirts, suits, shirts, athletic wear, infant clothing, bedding |

Soy Organic Cotton Jersey 60

Soy Organic Cotton Jersey 60

What is soy fabric?

With the softness of silk, soy fabric or “vegetable cashmere” is one of the world’s most eco-friendly fabrics. Produced using soy protein derived from the hulls of soybeans, this intriguing textile takes a waste product and transforms it into a usable textile with minimal use of toxic chemicals and limited processing.

Soy fabric has excellent drape, and it is highly elastic. While this textile dyes well, colors sometimes bleed during the first few washings. Though reasonably prone to pilling, soy fabric does not wrinkle, and it doesn’t shrink.

Soy fabric also has unique properties due to its chemical composition. For instance, this textile is UV-resistant, and it is also highly antimicrobial. Due to its light-reflective qualities, soy fabric looks like silk in addition to being very soft and lightweight.

Soy Wax and Ice Dyeing - Lynda Heines Fabric Design

Soy Wax and Ice Dyeing - Lynda Heines Fabric Design

History of soy fabric

Despite never achieving a significant level of popularity, soy fabric has a remarkably storied past. The great Henry Ford of Ford Motors fame is credited with inventing soy fabric, and he was known to wear soy garments toward the end of his life as part of his efforts to popularize soybean production in the United States. In 1941, for instance, he modeled a soy necktie in pictures taken on his 78th birthday, and he was also pictured wearing a suit composed of a mixture of “soy wool” and sheep wool fabrics.

Ford’s obsession with soy drove him as far as to produce a soybean car, and he also made an effort to incorporate soy fabric into his mass-production vehicles as frequently as possible. Starting in 1940, Ford initiated plans to produce a combined soy fabric and wool material for use in the upholstery for his automobiles. Due to the intervention of World War II, this project proved to be short-lived, but many Ford vehicles produced between 1941 and 1945 featured soy fabric sidewall upholstery.

During the war, Ford and other automotive companies started using new man-made fabrics like nylon for interior upholstery, and Henry Ford’s fixation with soybeans largely died with him in 1947. It would be more than 50 years before fabric pioneers once again took up the torch of soy fabric production.

In 1999, textile engineers announced the development of a new process that made the production of soy fabric considerably more efficient and less expensive. By 2003, this new production method had achieved a significant degree of popularity worldwide, and public approval of soy fabric improved substantially as consumer concerns over the environmental impact of common textile fibers reached a fever pitch.

Soy Organic Cotton Aubergine French Terry

Soy Organic Cotton Aubergine French Terry

Soy fabric today

Despite its impressive ecological sustainability and other desirable attributes, soy fabric has failed to achieve any significant degree of popularity. Within niche fabric production circles, however, soy protein fiber remains a textile fiber of choice, and many consumers will go considerably out of their way to purchase apparel and other items composed of soy fabric.

To this day, soy fabric remains the only textile composed of pure plant protein, and it’s also the only textile produced using food industry byproducts. Over time, it’s likely that a greater number of consumers will become aware of the unique benefits and attributes of soy fabric, driving this textile’s popularity higher.

How is soy fabric made?

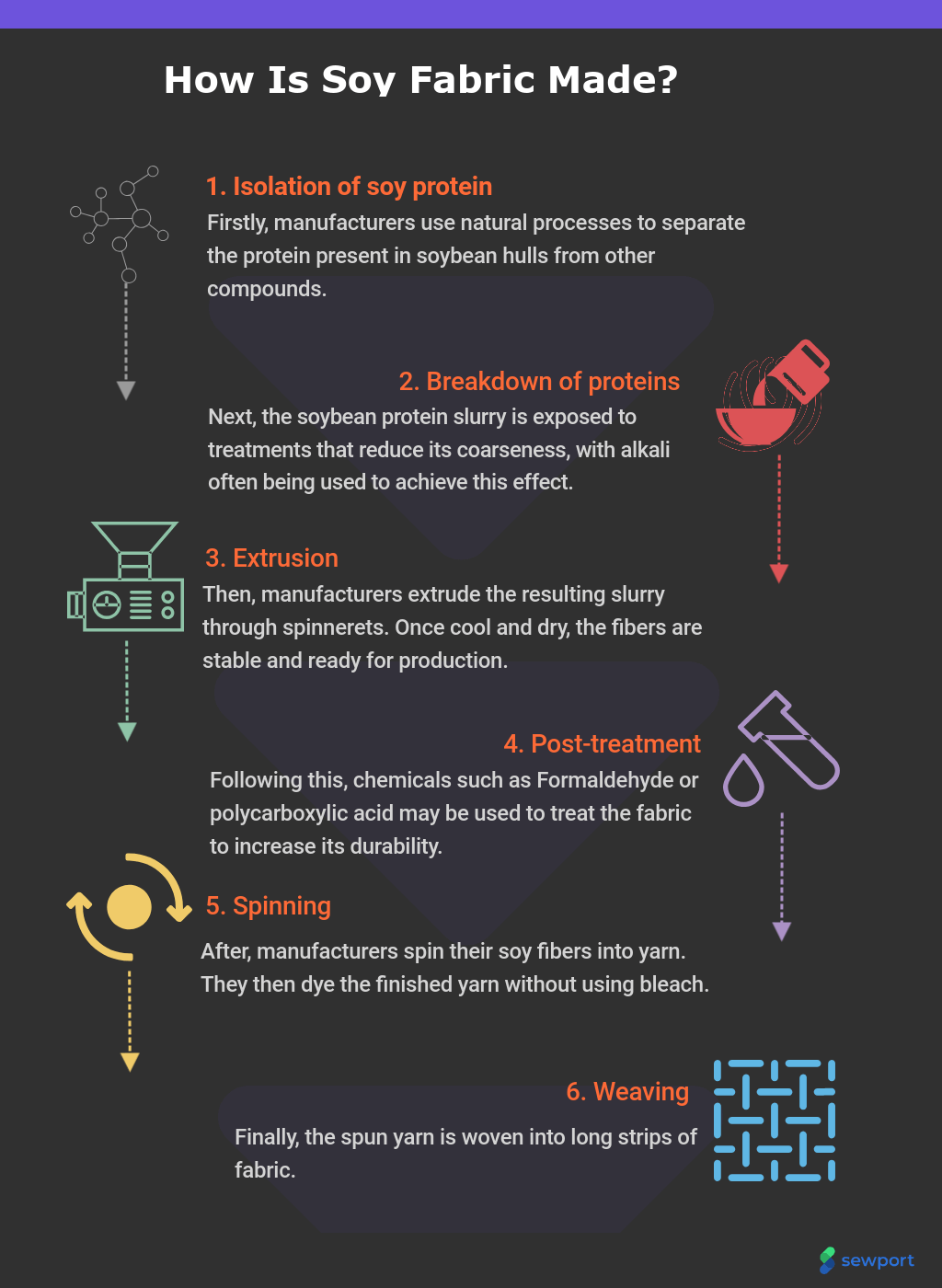

Soy fabric is derived from protein found in the hulls of soybeans. The processes used to produce soy fabric fibers vary significantly from manufacturer to manufacturer, and the best processes significantly limit or reuse the chemicals necessary to render soy protein into a usable textile fiber. Here’s a summation of the steps textile manufacturers take to produce soy fabric:

1. Isolation of soy protein

Soy fabric manufacturers use natural processes to separate the protein present in soybean hulls from other compounds. It’s also possible to extract protein directly from soybeans, but this practice is less popular. Soybean hulls are essentially valueless waste, but soybeans themselves have considerable market value, and hulls provide similar amounts of protein while being inedible.

Soy Jersey Knit Bay Blue

Soy Jersey Knit Bay Blue

2. Breakdown of proteins using heat, alkali, or enzymes

Soybean protein is not suitable for textile fiber manufacture in its natural state. To make soybean protein slurry suitable for textile production, it must first be exposed to treatments that reduce its coarseness.

In many cases, textile manufacturers use alkali to achieve this effect. While industrial alkali liquids can be reused, they cause toxicity issues if they enter the biosphere. Alternatively, textile manufacturers can use natural enzymes to render soy protein into a desirable state for fiber processing, which do not harm the environment. Most alkali and enzyme soy protein treatments also involve heat application.

3. Extrusion through spinnerets

After textile manufacturers have rendered soy protein into a desirable state, they extrude the resulting slurry through spinnerets. Once cool and dry, the resulting fibers are stable and ready for textile production. To improve the durability of the finished fibers, however, some textile manufacturers expose their soy fibers to formaldehyde treatments.

4. Post-treatment

Formaldehyde is a known carcinogen, which has led certain soy fabric producers to use polycarboxylic acids instead. Other soy fabric manufacturers choose to avoid exposing their fibers to finishing treatments altogether, but the resulting yarn is less durable and more prone to creasing.

5. Spinning

Next, soy fabric manufacturers spin their soy fibers into yarn. They then dye the finished yarn without using bleach since soy fibers are relatively delicate.

6. Weaving

The spun yarn can now be woven into long strips of fabric. Rolled onto bolts, this fabric is then sent to apparel or homeware manufacturers for the production of consumer products.

How is soy fabric used?

Soy fabric is usually reserved for apparel and accessories. Due to its natural elasticity, for instance, manufacturers commonly use this fabric to make tight-fitting women’s clothes like tank tops, dresses, and skirts. The high breathability of this fabric also makes it reasonably popular for athletic wear, but the low durability of soy fabric limits this textile’s popularity within this category.

Due to its impressive softness, soy fabric is a reasonably popular fabric for infant clothing and T-shirts for people of all ages. This luxurious softness also makes soy fabric desirable for bedding and even upholstery. When combined with wool, soy fabric is even useful as a material for men’s suits.

Where is soy fabric produced?

China is the predominant manufacturer of soy fabric simply because manufacturers in this country are more likely to adopt experimental textile trends. However, China is nowhere near the world’s biggest producer of soybeans with Brazil and the USA growing considerably higher volumes of this crop every year. Much of the raw material used in Chinese soy fabric production is, therefore, likely imported.

How much does soy fabric cost?

The cost of soy fabric is usually comparable to that of low-priced synthetic and natural textiles like cotton and polyester. In some cases, the novelty of soy fabric may drive the price of this textile material higher, but producing soy fabric does not cost considerably more than producing similar natural and artificial fabrics.

What different types of soy fabric are there?

Each manufacturing process results in slightly different forms of soy fabric, but this textile has largely universal traits. It is, however, possible to blend soy fabric with other textiles to improve or alter its properties. Here are a few examples of the available varieties of soy fabric:

1. Pure soy fabric

Soy fabric made strictly with processed soy protein is stretchy, breathable, and highly lustrous. Its durability is, however, relatively low, and dyeing pure soy fabric can sometimes be tricky.

2. Soy-cotton blends

Textile manufacturers commonly blend soy fabric with cotton to improve its durability. Blended soy-cotton fabrics retain the silk-like lustre of pure soy fiber while adopting the strength of cotton. As a result, apparel manufacturers commonly use soy-cotton blends to make athletic wear.

3. Soy-wool blends

While less common these days, Henry Ford briefly popularized combinations of soy fabric and wool during the mid-20th century. Blend soy-wool fabrics retain the elasticity and softness of soy fabric while benefiting from the insulative and durable properties of wool.

Organic Soy French Terry in Olive Green - The Confident Stitch

Organic Soy French Terry in Olive Green - The Confident Stitch

How does soy fabric impact the environment?

The environmental impact of soy fabric is complex and multifaceted. On its face, soy fabric is one of the most environmentally friendly fabrics since it is derived from a waste material. The production of soy fabric diverts waste from entering the landfill and provides it with an additional use.

Transforming soy protein into fabric, however, often entails the use of dangerous chemicals. While it’s certainly possible to produce soy protein without using alkali, other methods are more expensive, and especially in China, textile manufacturers commonly disregard ecological priorities in the pursuit of maximum profit.

Of special concern is the use of formaldehyde to strengthen soy fibers. Textile manufacturers should never use formaldehyde to produce fabric, and it is the prerogative of the industrial world to limit the use of this toxic chemical as much as possible.

Soy fabric manufacturers who do not use alkali and formaldehyde, however, produce one of the most eco-friendly fabrics ever made. In addition to being derived from a waste product, soy fabric is also highly biodegradable, so it is not a significant pollutant.

Soy fabric certifications available

Soy fabric may be eligible for certification by international organic textile certifiers like OEKO TEX. Textile manufacturers producing soy fabric in the United States or European Union may also be eligible for USDA or European Commission organic certification.