| Fabric name | Velvet |

| Fabric also known as | Velveto, velveteen |

| Fabric composition | Multi-layered fabric with dense piles that are soft to the touch |

| Fabric possible thread count variations | The threads in velvet fabric are always bunched closely together |

| Fabric breathability | High |

| Moisture-wicking abilities | Medium |

| Heat retention abilities | Medium |

| Stretchability (give) | Low |

| Prone to pilling/bubbling | Low |

| Country where fabric was first produced | Unknown; most likely East Asia |

| Biggest exporting/producing country today | Varies depending on the fabric that is used to make velvet |

| Recommended washing temperatures | Hand wash or cold |

| Commonly used in | Upholstery, wall hangings, dresses, eveningwear, formal robes, dresses, bedding, hats |

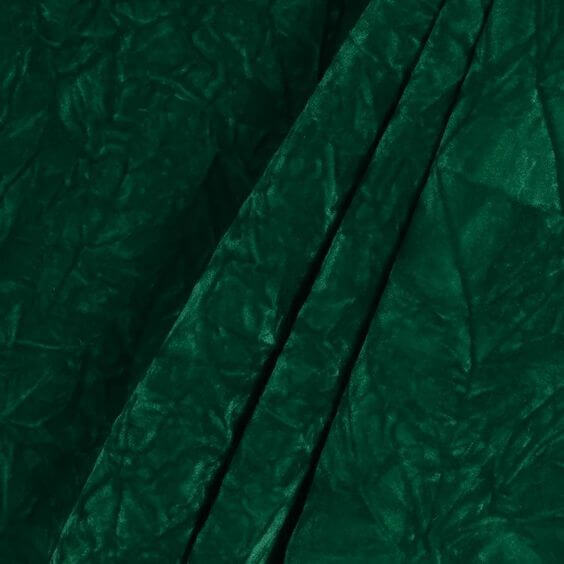

Emerald Green Crushed Flocked Velvet Fabric

Emerald Green Crushed Flocked Velvet Fabric

What is velvet fabric?

Velvet is a sleek, soft fabric that is commonly used in intimate garments, upholstery and other textile applications. Due to how expensive it was to produce velvet textiles in the past, this fabric is often associated with the aristocracy. Even though most types of modern velvet are adulterated with cheap synthetic materials, this unique fabric remains one of the sleekest, softest man-made materials ever engineered.

History of velvet

The first recorded mention of velvet fabric is from the 14th century, and scholars of the past mostly believed that this textile was originally produced in East Asia before making its way down the Silk Road into Europe. Traditional forms of velvet were made with pure silk, which made them incredibly popular. Asian silk was already very soft, but the unique production processes used to make velvet result in a material that’s even more sumptuous and luxurious than other silk products.

Until velvet gained popularity in Europe during the Renaissance, this fabric was commonly used in the Middle East. The records of many civilizations located within the borders of in modern Iraq and Iran, for instance, indicate that velvet was a favorite fabric among the royalty the region.

Black Velvet Jodhpuri Bandhgala

Black Velvet Jodhpuri Bandhgala

Velvet today

When machine looms were invented, velvet production became much less expensive, and the development of synthetic fabrics that somewhat approximate the properties of silk finally brought the wonders of velvet to even the lowest rungs of society. While today’s velvet may not be as pure or exotic as the velvet of the past, it remains prized as a material for curtains, blankets, stuffed animals, and all manner of other products that are supposed to be as soft and cuddly as possible.

How is velvet fabric made?

While various materials can be used to make velvet, the process used to produce this fabric is the same regardless of which base textile is used. Velvet can only be woven on a unique type of loom that spins two layers of fabric simultaneously. These fabric layers are then separated, and they are wound up on rolls.

Velvet is made with vertical yarn, and velveteen is made with horizontal yarn, but otherwise, these two textiles are made with largely the same processes. Velveteen, however, is often mixed with normal cotton yarn, which reduces its quality and changes its texture.

Silk, one of the most popular velvet materials, is made by unraveling the cocoons of silkworms and spinning these threads into yarn. Synthetic textiles such as rayon are made by rendering petrochemicals into filaments. Once one of these yarn types is woven into velvet cloth, it can be dyed or treated depending on the intended application.

How is velvet fabric used?

The main desirable attribute of velvet is its softness, so this textile is primarily used in applications in which fabric is placed close to the skin. At the same time, velvet also has a distinctive visual allure, so it’s commonly used in home decor in applications such as curtains and throw pillows. Unlike some other interior decor items, velvet feels as good as it looks, which makes this fabric a multi-sensory home design experience.

Due to its softness, velvet is sometimes used in bedding. In particular, this fabric is commonly used in the insulative blankets that are placed between sheets and duvets. Velvet is much more prevalent in womenswear than it is in clothing for men, and it is often used to accentuate womanly curves and create stunning eveningwear. Some stiff forms of velvet are used to make hats, and this material is popular in glove linings.

Where is velvet fabric produced?

Like most types of textiles, the largest share of the world’s velvet is produced in China. Since this fabric can be produced with two different types of textiles, however, it’s important to touch on each variety in turn:

Largest producer of silk

China is the world’s largest producer of silk, but it is followed closely by India. As a general rule, Indian silk is more likely to be certified, and it is usually higher quality.

Cadencia Velvet Gown - Emerald

Cadencia Velvet Gown - Emerald

Largest producer of rayon

China leads the world as the most prolific producer of synthetic textiles. These and other reckless industrial practices have rapidly made this communist nation the world’s largest polluter as well, and China is lagging far behind the rest of the world’s gradual switch to sustainable fabrics and non-polluting production processes.

How much does velvet fabric cost?

Velvet made with synthetic materials is generally quite inexpensive. Full-silk velvet, however, may cost hundreds of dollars per yard since making this fabric is so labor-intensive. Velvet fabric that is woven with care using sustainable materials will always cost more than fabric that was made cheaply using synthetic textiles.

What different types of velvet fabric are there?

Over the centuries, dozens of different types of velvet fabric have been developed. Here are a handful of examples:

1. Chiffon velvet

Also known as transparent velvet, this ultra-sheer form of velvet is often used in formal garments and eveningwear.

Dapple Velvet

Dapple Velvet

2. Crushed velvet

Perhaps one of the most distinctive forms of velvet, crushed velvet offers a varied texture that is achieved by either pressing or twisting the fabric when wet. Rather than having a uniform surface, crushed velvet rises and falls in a way that is both randomly organic and visually fascinating.

3. Embossed velvet

This type of velvet has words, symbols, or other shapes embossed into it. The embossed section is slightly shorter than the surrounding velvet, and in most cases, this embossing effect can also be felt to the touch.

Golden Chartreuse Hand Dyed Silk Velvet Fabric

Golden Chartreuse Hand Dyed Silk Velvet Fabric

4. Hammered velvet

Considered to be one of the most lustrous forms of velvet, this type of fabric has been firmly pressed or smashed rather than crushed. The resulting fabric is dappled and highly reminiscent of the coat of a soft, warm animal.

5. Lyons velvet

This type of velvet is much denser than other varieties of the fabric, which results in a stiff textile that is ideal for various outerwear applications. From coats to hats, Lyons velvet is considered to be one of the most luxurious outerwear materials in existence.

Jenny Yoo Bridesmaid Dress Ellis

Jenny Yoo Bridesmaid Dress Ellis

6. Panne velvet

While the term “Panne” can mean multiple things in relation to velvet, this term originally designated a type of crushed velvet that was subjected to a specific single-direction thrusting moment. These days, Panne is more widely used to refer to velvet with a bunched appearance.

7. Utrecht velvet

This type of crimped velvet has largely gone out of style, but it is sometimes still used in dresses and eveningwear.

8. Voided velvet

This type of velvet features patterns made from sections with pile and sections without. Any number of shapes or designs can be made, which makes this type of velvet similar to embossed velvet.

9. Ring velvet

Originally, velvet could only be considered “ring velvet” if it could be drawn through a wedding ring. Essentially, ring velvet is incredibly fine and light like chiffon.

Twisted Tailor super skinny suit jacket in burgundy velvet

Twisted Tailor super skinny suit jacket in burgundy velvet

How does velvet fabric impact the environment?

Since “velvet” refers to a fabric weave instead of a material, it can’t technically be said that velvet as a concept has any impact on the environment. The different materials used to make velvet, however, have varying degrees of environmental impact that should be carefully considered.

Environmental impact of silk

Silk is the closest thing we have to an ideal fabric from an environmental standpoint. This fabric is still, in most cases, produced the same way it has been produced for thousands of years, and since the production of silk is not aided by any pesticides, fertilizers, or other toxic substances, making this fabric does not have any significant negative environmental impact.

Environmental impact of rayon and other synthetic textiles

Rayon is the most commonly used substitute for silk in velvet and velvet-inspired fabrics, and the production of this synthetic substance is significantly harmful to the environment. The rayon production process involves multiple chemical washes, and the base material of this substance is petroleum.

Essentially, rayon is non-biodegradable fossil fuel product that introduces tons of harmful chemicals into the water supply as it is created. With these detractors in full view, the only reason that rayon is still produced is that it is inexpensive.

Velvet fabric certifications available

Depending on the material that was used to make a velvet fabric product, a variety of certifications may be awarded:

Silk certifications

Silk Mark is the world’s leading authority on silk sustainability and quality, so always make sure that your silk is certified by this independent Indian organization. Silk production has been part of Indian life for millennia, and Silk Mark makes sure that companies afford proper cultural, environmental, and humanitarian considerations to the silk they produce.

Synthetic material certifications

The Global Recycled Standard (GRS) will certify synthetic textiles if they can be demonstrated as containing only recycled materials. However, rayon, which is the primary constituent of synthetic velvet, is very hard to recycle, so new materials are usually used to make this common velvet constituent.