Welcome to the most comprehensive guide on “How to start a clothing line?” in the internet. For 2023 - we put together The Total Clothing Line Starting Guide - as we prefer to call it.

With the help of a team of fashion experts and consultants who shared their most in-depth knowledge on starting a clothing line, thorough market research on costs of starting a clothing line (go to Section 3 – Costs of starting a clothing line right away If you want to see the results of the numbers, we crunched for you) and some fantastic tips. And then to top it all off, we went out and asked 43 Fashion Experts and brands to share their biggest secrets and helpful suggestions for newcomers, so that you can avoid all the pitfalls (in section 5 – Tips on starting a clothing line ). Learn from experiences of other brands who have been through this all and are not shy to share it with you.

For some, the question of How to start a clothing line is ever daunting. Opening a fashion business is the ultimate dream for any designer. Whatever route you take to achieving this goal, there is one defining factor that stands above everything else in realising it: your passion and persistence . These qualities can lead to a successful career or business idea but there are some key points to consider when getting the initial idea off the ground.

So, read on for your complete step by step guide:

For many new fashion designers, having little or no experience in actually running a business is no longer a setback. That’s not to say that it’s an easy process bringing your brand to fruition but with a solid plan and handy tools to help get you started, getting your label off to the right start is a lot simpler than you might think.

Starting a fashion line can be quite difficult especially if you are doing it for the first time. As a creative person, you can have great ideas about how to create something that you love that fits your needs and others like you. But this is not enough. There are a lot of practical aspects involved in fashion, much more than just sketching nice clothes. How example you might want to start a children’s clothing line.

◦Finding manufacturers, deciding what fabrics you should use for your products, buying them at a good price, marketing and advertising your clothing brand , delivery – all these can be overwhelming for a beginner. Despite all these challenges, there are still ways to become successful by doing the things that passionate you.

If you’re thinking about embarking on a new venture, take a look at some of our top things to consider when starting your own fashion brand:

- Do your research

- Plan and commit

- Create a business plan

- Create a brand identity

- Production and sourcing materials

- Marketing strategies

1. Basics: The business of starting a clothing line

Creativity and passion are the driving forces of starting out in fashion, but it takes a lot of business savvy to make your ideas work in the long term. There are a few steps to consider before you get to the production phase, so check them out below to build the foundations of your fashion business.

1) Do your research

So you have a brilliant idea that will disrupt the fashion industry, now it is time to start researching. It might sound time consuming but research will provide key data about your target audience and competitors, and give you the information you need to decide your niche.

This is also the time to find out more about the type of clothing you are planning to produce and get to know all your competition. Talk to experienced professionals, find out what people are looking for and identify the gaps in the industry that you can fill. Competition is fierce and you must have a secret weapon to set you apart from hundreds of other small businesses, be it original design, durability and functionality, quality or competitive pricing.

Don’t underestimate market research . Costs and price information must also form a part of this too. Considering the price and costs of producing your clothing will ultimately decide what place your product has in the market to make good returns.

When you feel confident you have covered the initial research, you’re ready to start the next stage - planning .

2) Plan and commit

Planning creates the foundations for your fashion business. There are several elements that go into this stage, starting with the first question - are you going it alone or create your brand with business partners? If you are not alone, make sure you and your partners are on the same page, you agree on the type of garments you will be producing, and you share the vision of your company’s future.

After you’ve decided who has creative control, take a look at the types of areas to cover when completing your business plan.

3) Create a business plan

This might sound like an obvious one but creating a solid business plan will help you stay on track during the initial stages of development. Even if you have a basic idea in your head, look at everything in detail to highlight any potential issues or shortfalls. Deciding who your fashion business is suited to and building your identity around this, will tailor your clothing company to the target market and speak to the right people looking to buy into your style and brand culture.

The main areas to consider in a business plan are:

- Start-up costs and finance

- Legal aspects and trademarking

- Creating a brand identity

- Production and sourcing

- Marketing your brand

4) Legal aspects of your new business

Now, let’s legalise your business. Registering a new business is hardly an exciting task when you are eager to start manufacturing. However, it is best to set aside your creative impulses and educate yourself on trading technicalities.

Sole entrepreneur or registered company?

Will your company be a sole proprietorship or come under a ‘Limited’ organisation? If you choose the former, you have the sole responsibility for all your assets and liabilities accrued by the business. In the latter, you have to register the company legally with all of your partners to avoid any legal issues.

If you are going into the clothing business as a brand owner with one or multiple partners, you become stakeholders. Do not leave any loopholes and document clearly the benefits each company member is entitled to. Who is responsible for which area of the business and how much work they commit to putting in. Make sure you put this on paper when you incorporate the company. You never know how successful your brand might be and you don’t want to be left out or pushed out of your venture as soon as it picks momentum.

Have you chosen a name yet? Your company must have a unique legal name. To make sure it is not already taken you can resource to googling the word, phrase or a combination of phrases you want to use as your business name. If you are unsure, consult with a layer. In fact, find a good lawyer who is able to advise you on the most crucial aspects of setting up a clothing brand, like the tax structure. What are the benefits of setting one type of company over another? As a designer, you might not care, but as a business owner, you must do everything in your power to ensure you have the highest revenue possible.

5) Consider brand trademarks

Another issue that you might encounter down the line is people stealing your designs and ideas. To become successful in the clothing industry, good fit and unique design are key. The original ideas created by you and your team can be easily looted when your photos hit social media, ads and fashion trade shows. To avoid imitation, think of a way you can protect your unique designs. If you can trademark a logo or a concept – it may be a worthwhile investment.

6) Create a brand identity

During the planning phase and before you start marketing your brand, you need to establish your identity. This process involves looking at the research and data you collated in the initial phase to create personas of the type of people that will want to buy your clothing. You may have the basic idea of how you want your brand to look and they type of people it may appeal to, but tweaking this will ensure you grab that slice of the market.

A fashion brand isn’t just about the clothing, it’s about the people who wear them. Building your brand to fit this concept will help to immerse your message into their lifestyles as well as their wardrobes.

7) Production and sourcing materials

Choosing a suitable clothing manufacturer can feel like a daunting task for anyone starting out in the industry. By using Sewport, our innovative platform takes away the hassle of searching the Internet for fashion factories and fabric suppliers. With a simple user-friendly interface, you can filter requirements with the click of a button. A personalised dashboard enables you to send quote requests, ask questions and place orders to make the whole process straightforward from start to finish.

This stage in your business plan enables you to the identify costs of production and factor in other elements such as lead times, quantities and margins for error.

8) Marketing your clothing brand

Part of the planning process should consider how you will promote your clothing brand to the right people. This intrinsic stage can make or break the future of your new clothing line before it has made it to production. Creating a buzz before, during and after launch is key to enticing customers with a new and exciting product. Plus, listening to consumers throughout this stage also helps develop the business in the long term.

There are several marketing techniques that are a must for new start-ups. Check out some of the areas you should invest in when spreading the word about your new brand.

Create a website

In the 21st century creating your own e-commerce website is a must . Your website will serve multiple purposes for your business. First of all, it is a face and business card of your brand. Secondly, having a website can instantly showcase your garments to the world, or even sell your clothes online straight away. There are some amazing tools out there to use to develop a good looking website wireframe but you can lso use UX Company to do that for you.

If you are on a tight budget an e-commerce solution like Shopify is a great starting point. You do not have to be a web designer or hire a team – they already have pre-prepared designs ready to use with a simple shopping cart feature, so you can start selling straight away. If you are starting off big or want something unique, hire a professional to create something individual to your brand.

Design wise, don’t get carried away. It is important to keep in mind your target audience. You want your audience to have a smooth user experience and easily navigate around your website without any extra effort.

Use social media to boost your brand

Social media is a must-use marketing tool for both new and established brands. There were 2.46 billion active social media users across the globe in 2017 and unsurprisingly this number is set to rise to around a third of the entire world’s population by 2021! So getting in front of the growing audience is vital.

Social influence

Top companies use popular influencers and celebrities for their brand endorsements which help to boost their sales. Famous athletes, singers and actors wearing the product on and off the red carpet definitely caught your attention at least once. This is smart marketing. Their ads keep playing on TV, the product gets mentioned in Youtube videos and appears on other social media platforms which attract their existing fans and followers to convert into new customers.

The key is to identify influencers in your niche and pitch them your brand and styles. Influencer marketing does have it pros and cons, and it doesn’t guarantee new sales. However, with the right targeting you can use this effective tool to boost your presence.

By using top analysis tools, you will have a variety of insights to make the most of your influencer budget.

Social recommendations

Before people buy your product which is not well known yet, they will want to know more about it, and ideally, get a recommendation from someone they know or admire. Try to see if you, your friends or social influencers can do a short video review or post an online review of your brand or specific products. This way you can steer those people who are still hesitating about purchasing your new exclusive product in the right direction.

A recommendation is one of the most powerful marketing tools for business, and getting authentic and genuine feedback can build a loyal customer base.

Key points when marketing your brand

- Define the age group of people you want to attract and create the marketing strategy accordingly. The techniques that you use will heavily depend on the type of audience you target, it must be relevant and effective.

- Keep it simple! Use the language people understand. When launching a clothing brand do not neglect marketing, as promotions and advertisements will play a key role in the growth of your clothing line. More advertisements give more exposure and often lead to higher sales when implemented effectively.

Congratulations on tackling the planning stage. You are now ready to set up a new clothing brand! Take a look at how to take the next steps and start producing your first collection:

- The ideation stage

- Create a Tech Pack

- Fabrics and materials

- Screen printing, embroidery and labels

- Pattern making

- Samples

- Preparing for production and ordering materials

- Agree timelines with the factory

- Packaging and quality control

2. Product: How to create your clothing line

Knowing the exact steps you need to take from your initial idea to the final product will make your communication with the clothing manufacturers much smoother. It will also save you a lot of time, stress and money along the way.

Our simple guide will take you through the whole process to help you get started on your first product.

1) The ideation stage

First, create a sketch, a drawing with your design. If you already own a piece of clothing that you want to modify then take some pictures and make sketches on top to instruct the factory about the changes you want to be made.

2) Create a Tech Pack and digitise your designs

A tech pack is a blueprint of your designs and includes everything about how you want your products to be made. This process may seem complicated, but in fact, it’s just detailed specifications of each garment style. This information is important in the production process and helps to translate your ideas to the clothing manufacturer.

If you’re unsure how to create a tech pack, you can search for a consultant or a designer on Sewport to help you finalise your idea and turn them into a computer-aided design (CAD) drawing. There is also the opportunity to create your own tech pack from the Sewport dashboard. This tool is simple to use and can be sent straight to clothing factories when requesting quotes and information.

Benefits of creating a Tech Pack for your garments are:

- Accurate quotes

- Fewer sample trials, since your idea is well documented and described

- Less room for error or misunderstanding – you can always refer back to the technical documentation in the Tech Pack

3) Get your file formats right

Make sure you supply a design in the right size, dimensions and file type. The printing company doing printing or embroidery will not be able to work with standard files. Instead, you can supply files such as .ai and .psd in vector format. If you only have a .jpeg, do not worry, it is easy to find a freelancer who can cheaply convert raster to vector.

For more details on how to prepare a full Tech Pack, refer to our article - Eliminate Clothing Manufacturing Errors: How to Make a Tech Pack.

4) Fabric and materials

Consider what fabric, lining, zips and trims you want to use. Be specific about the fabric composition, weight and colour. Do not forget to add this information to your design specifications and tech pack.

Not all colour options are available when you are buying only a couple of metres for sampling. It will take longer to produce a custom colour of the fabric or trims than purchasing off the shelf stock options which are usually available with short lead times.

5) Printing, embroidery and labels

If you are going to have a design on your garment, you need to decide where it should be placed. You will also need to consider or discuss with your potential manufacturer various garment printing methods and types to choose what is best for your design and garment type.

Measure the placement and record it in the tech pack. This placement forms an important part of the production process, as some logos and prints may not work well on different fabrics. Clothing labels and their placement are also an important consideration and should include details of print or tag design based on your requirements.

It’s essential to give the clothing producer specific measurements for any artwork (height x width or diagonal) and its placement (for example, 30 cm down from the highest shoulder point and 20 cm left from the side seam, etc.). The best way is to make a visualisation of the placement in your tech pack.

6) Pattern making

Next, you need patterns cut of your designs. What are patterns and what is pattern making? Patterns are construction blocks and blueprints for your garment. Unless you have experience of pattern cutting, searching for a specialist on Sewport will ensure you get the best results.

Imagine a plain basic T-shirt with all the seams. It has 4 panels – 4 parts: 2 sleeves, the front and the back. Now imagine you unpick all the seams from this T-shirt and put the pieces of fabric on the table. You have 4 pieces of a specific shape. The shapes are cut from fabric using the template shapes created by a pattern cutter. These are required for production to be consecutive so that each item has the same measurements and fit.

No great effort is required on your end, just find a pattern cutting professional who can help. An important note is to ask the pattern cutter about the ownership of the patterns before you engage. It is also good to know if your pattern cutter can supply you with patterns in a digital format. This will save you some time when working with a clothing manufacturer, as you will be able to supply the patterns electronically.

Most clothing factories can work with any pattern format, but more modern production companies prefer digital ones. Lektra, Assyst, Gerber are the top choices of pattern making software.

7) Samples

Sample making is the most important stage. Exciting as it might be, it often takes a couple of rounds of samples before you feel the garment is perfect. Do not expect the clothing manufacturer or sampling studio to get it right on the first trial. It is not something that happens very often. Keep in mind that you are creating a completely new product with the combination of fabric, design and fit that has never been done before. Some practise and adjustments will make it perfect.

8) Test your product

Test your sample rigorously. Wear it, stretch it, wash it, wear it again. See if the fabric shrinks or stretches out after washing and by how much. Adjust your next sample accordingly. If it is a sports item then test its comfortability and utility use. Do the seams hold? Does the print stay on or it washes away? Real life testing is important as you do not want to get a negative feedback from people after wearing your garment for a week or two.

Look at the details and finishing of the garments too. Pay attention to the finer details. If you notice something that is not quite right, or you see the room for improvement, raise your concerns with your apparel production company. They should find a way to improve your garment as long as you can explain what you need.

9) Grading and sizing

When your factory completed the sample production process and the item is approved for bulk production ask the clothing factory to grade the patterns to other sizes. As the grading is completed it might be a good idea to see the sample in a different size, just to compare and see if it is consistent with your expectations. There are standard grading rules and grading steps a manufacturer will follow. You have to have a size spec for all sizes.

If you want custom sizing, it is generally a good idea to check what the grading steps are and if you feel they are in line with your vision for the fit of the garments across all sizes. This especially relates to the oversized items, tight-fitting items or items with specific design or purpose. In these cases, standard grading rules probably will not apply so check the measurements spec to make sure it reflects the uniqueness of your design. It is worth noting, anything outside of the standard grading specifications may not be as cost effective to produce, as they will require specialised tooling and production specific to your brand. Make sure you check everything and also check out some clothing line mistakes to avoid.

10) Preparing for production and ordering materials

When all sizes are approved and grading is done, give your clothing manufacturer the exact breakdown of the quantities per size and the total quantity and a line sheet. Based on that they will be able to give you the total order of fabric consumption for your desired quantity. Ask them to mention all fabrics (e.g. main, lining) and all trims.

Requirements for trims such as elastics, interlinings, straps, clasps and more are often overlooked. Ask your manufacturer to list the trims they need for production. Find out what factories can supply or source on their own, and what fabric and trims you need to source and supply to them.

Higher quantities will always have better margins and lower production prices. Ask for what the economic order quantity is and weight in on what order quantity will make sense to you and your desired profit margins. However, there are options for fashion brands looking for factories to produce smaller runs. These may be a more expensive option, but for smaller brands, it avoids having high stock levels in the early stages of your business.

11) Minimum order quantities and fabric availability

Have a list of all suppliers for fabrics and trims and start negotiating the order pricing as soon as possible. Research the minimum orders and stock availability. You can easily find yourself in a situation when the minimum order quantity (MOQ) for a specific colour or article is more than you expected or can afford.

Getting a hold of this information early will allow you to adjust the production quantity or look into alternative suppliers. Fabrics and trims from stock can run out, be sure they are in stock by the time you need them. It may be a serious blocker for your production if you don’t make a solid enquiry and the fabric you were planning to buy is suddenly out of stock. You can avoid this by planning ahead with the supplier.

12) Custom orders and designs

Custom orders for fabric and trims may take a long time to process, weeks or even months. Make sure you are aware of that and once you know the exact timeline of production and delivery let your clothing manufacturer know. They carefully plan their production capabilities with allocated time-slots and will not sit around all day waiting for your fabric to arrive tomorrow, next week or next month. If you are ready to launch and have a slot booked but the fabric did not arrive on time, there is a high possibility your order will be set aside and you will have to wait for the next production slot.

14) Finding a clothing manufacturer or factory for you

Depending on your production quantity and goals you want to achieve, you may want to consider different factory types. There are FPP (Full production factories) and CMT (cut make trim factories) – there are differences between these two, so be sure you know. Regardless it will be very important for you to know how clothes are made, so you have a clear understanding what the factory will do with your design to produce it. Once you finally narrowed it down be sure you know how to talk to a clothing manufacturer to get the best out of it and not fail with any negotiations, or simply have too low or too high expectations of what it can and could be.

Here are some good tips on selecting a garment factory right for you.

Consider both local, overseas and near-shore manufacturers. Say for instance if you are in the UK here are the things you can consider when working with UK fashion factory. All will have their own benefits and drawbacks. The further from you, the more likely you will have a longer lead time, but usually a better price. The closer to you, the more control you can have over the process by simply dropping by and visiting your manufacturer or simply talking to them face to face. Do not expect the manufacturer to allow you to be at their factory all day long and hands on. For this you will need a sampling studio or a very small batch clothing manufacturer who will work 1-2-1 with you to finalise your samples first.

14) Production lead times

Lead times on fabrics and production is often a fixed time frame due to sourcing and availability. Make a timeline for production with your clothing factory. Agree on when the final product should arrive and ensure the manufacturer has everything to start production well ahead of the launch date, not after. Plan ahead and make a checklist with the factory if you need to.

Remember, any sudden changes in your design will reflect in the lead time. It’s also worth noting that last minute changes can set you back weeks, as you will have to repeat the first steps again to approve the design with the new changes.

15) Packaging, quality control (QC) and delivery

Find out what packaging and delivery options you have. Specify your delivery address and try to get a ballpark estimate for delivery as well. Budget in the cost of delivery to your plan. When the items arrive thoroughly check as much as you can against your specifications and approved sample. The sooner you raise an issue with your manufacturer the better.

Above all, do not stress if things go wrong and not as planned. Production of garments is a complicated and lengthy process that involves an array of fashion specialists and departments within one or more companies. Having contingencies and considering margins of error is an important metric in your plans that will help keep you focused on the launch of your new products.

If you’d like more information on the clothing production process, check out our guide to working with clothing manufacturers.

Sound impossible? Well, with the resources, information and platforms available in today’s online sphere, starting a clothing line with absolutely no contacts and no experience in business is now a real possibility.

Before you even begin to work on your business and attempt to have your clothing created, there are several things you can do to prepare yourself for the journey ahead and ensure you make the best decisions for your brand at each step of the process.

3. Costs: How much does it cost to start a clothing line?

How much money do you need to start your own clothing line? You won’t be able to make a solid business plan for your fashion business if you don’t properly understand the costs. We decided to make this guide on the costs of starting a clothing line so you can be better informed.

There are many factors involved in determining the cost of starting a clothing line, but we’ll do our best to give you a ballpark estimate of what you will end up paying. In order to do this, we’ll try to make reasonable assumptions about what a typical entrepreneur will do.

In general, we assume that you’ll try and get the best value for your money. You’re not going to be using the cheapest provider and sacrifice quality, but you also won’t pick the most expensive option.

We’ll also include the costs of selling clothing online. We’re going to assume that as a starting brand you won’t be able to sell your clothing to retailers.

All of the prices you see here are based on real prices we found on the internet. If you want to take a look at the sites for yourself, you can check out this google doc .

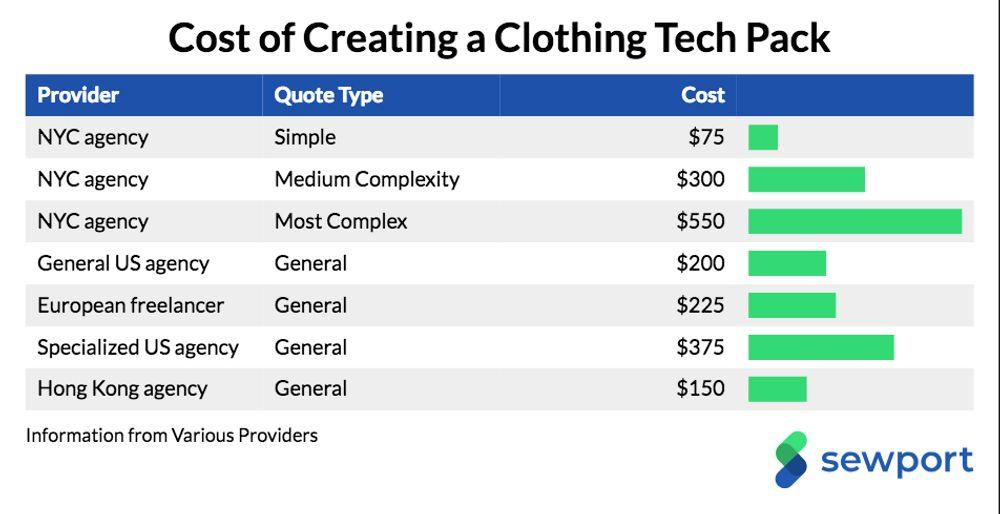

1) Price of creating a tech pack

The first thing you’ll need to when creating a clothing line is to create a “tech pack”. A tech pack is a set of documents that explain to a manufacturer the details of a piece of clothing so they can manufacture it correctly.

If you work with Sewport, you won’t need to worry about this step since it’s a part of the overall process of using our platform to work with manufacturers. Still, we’re mentioning it here since we recognize that it’s a common step for many clothing brands.

Typically, a tech pack will contain drawings, diagrams, sketches, measurements, and other components. It’s a professional document that you can’t make yourself unless you’ve had the proper training.

For that reason, it’s typical to work with a freelance fashion designer or a freelance fashion agency to create a tech pack. Here are some typical prices we found for getting tech packs created:

The simpler a garment is, the less work goes into making a tech pack. For example, it’s less work to make a tech pack for a t-shirt than for a dress with complicated frills and patterns.

Because of that, some agencies and freelancers have a sliding scale of prices that they may quote you for a tech pack. Other agencies just have a single price that they charge for most/all tech packs.

We found prices from several agencies and one freelancer across the globe. Generally, the prices were around the $200-$300 range, so that’s the price you should expect to pay for each garment in your clothing line.

2) Cost of making a sample

The next step in setting up a clothing line is to turn your tech pack into an actual sample. It’s important that you actually see and feel your product before you start selling it to customers.

You’ll most likely order a sample from the same manufacturer you’re using to make your final products, but we did find a full-service fashion agency in New York City that does both tech packs and samples.

We included the prices here of various providers across the world so you can see how much different options cost.

Again, if you work with Sewport, you won’t have to worry about this step of the manufacturing process. It’s included when manufacturers send you bids on your project.

Expect to pay much more for one sample piece than you will for one piece in the final production run. The reason for this is that making just one piece of a brand new garment is expensive for a manufacturer. They might not have the exact materials or colors for your particular garment.

We found that samples from American agencies and manufacturers tend to be more expensive than samples from Asian manufacturers. This is to be expected as manufacturing and labor are generally more expensive in America.

If you’re working with a manufacturer in America, expect to pay around $200-$300 for a sample. If you’re working with a manufacturer in Asia, expect to pay around $50-$150 for a sample.

Remember that these prices are for only for one piece of clothing. You’ll have to buy a sample for each design in your clothing line.

3) Cost of manufacturing, storage and shipping clothing

Now that you’ve approved samples for your clothing line, it’s time to actually manufacture and sell your clothing.

The costs for manufacturing, storing, and shipping clothing can vary drastically based on your situation. We’ve made these assumptions here as there are potentially dozens of variations that could affect your situation:

- You’re manufacturing from a Chinese factory. It’s a common choice for manufacturing and there are many shipping options available to you.

- You will only order 100 units of each product. We’re just exploring here how much it costs to start a clothing line. As you get more customers, you’ll probably want to order more.

- Your manufacturer will charge you market rates. We looked at several providers for each article of clothing and used the average price in our calculation.

- You’re going to start by manufacturing t-shirts, hoodies, leggings, and/or dresses. These are some of the most common products we see manufactured.

- You’re going to use a fulfilment warehouse to receive and ship your products. While you can initially do this out of your home, you’ll need a professional solution if you become big enough.

- You will ship your products to a warehouse in America via air. You can save a little by using ocean freight but your clothes will arrive in 30+ days instead of 5 days.

- All of your customers are in America and don’t ask for expedited shipping.

What we found is that all of the variations here come down to how expensive each article of clothing is to manufacture.

T-shirts are the cheapest to create at around $3 each. Dresses are the most expensive at around $10 each.

We found quotes for shipping from China to the USA from Freightos . We found that small variations in weight and volume didn’t affect our shipping rates. That’s why 100 pieces of any of these types of clothing cost $1,150 to ship to America.

We found two fulfillment warehouses that charge $2.50 per item to receive, store and ship each article of clothing. You do have to pay shipping costs which come out to three dollars per item sent.

Add all of these costs together and you see that you have at least $2,000 in costs for every article of clothing in your line.

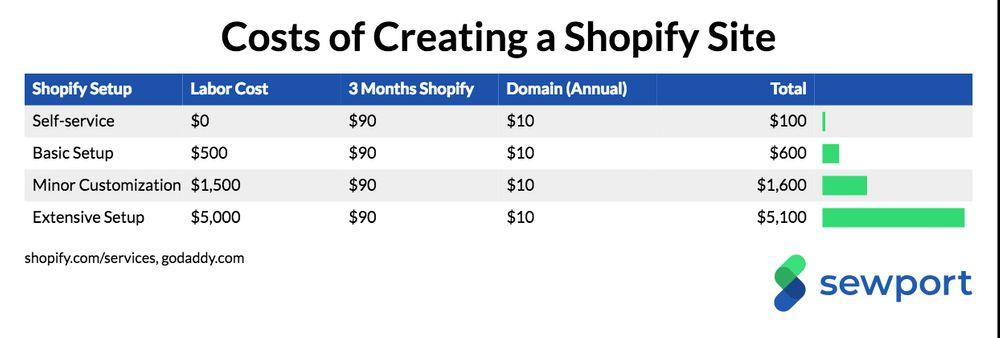

4) Cost of setting up a website

Now that we have calculated the costs for manufacturing and shipping our clothes, we have to create an online store for customers to find out about our brand and buy our clothes.

There are many options for making a professional eCommerce site. We’re only going to show the costs for a Shopify site since it’s well-known and many of the other platforms have similar costs.

While you can setup Shopify yourself, it might take you a bit of time to create a professional looking site.

You may want to hire someone to create a basic Shopify site for you. It will cost you at least $500 and possibly more depending on how complex you want your site to be.

Shopify installs can cost even more than that, but it’s not likely that you’ll need something that complicated when first starting out.

We’re only showing three month’s worth of cost of Shopify (at $30 each month) since we’re being optimistic and assuming that you’ll sell out your initial inventory within those first three months.

Add in a $10 annual fee for a custom domain and the total for a website comes out to something between $100 and $5,100. Most likely, you’ll be at the lower end of that range when starting out.

5) Revenue and profits for a small clothing line

Now let’s put all of these numbers together. Let’s say you want to start off as an extremely small clothing line with only four products.

You don’t have that much money, so you try and do as much work yourself as possible. You set up the Shopify site and do all the marketing yourself.

Since you’re trying to minimize costs, you create simple designs that don’t require as much money to design and manufacture. This means that your products don’t sell for as high a price.

Here’s what your costs and revenue might look like:

After adding up all expenses, you’d want at least $12,000 to fund this small clothing line. Ideally, your total sales will be $13,500 and you’ll end up with a profit of $1,225.

If this seems low to you, keep in mind that the fashion industry has a profit margin of around 4.5% . In this scenario, you have a profit margin of around 9%.

A lot of your money went into upfront costs like creating a tech pack and buying samples. If you continue to sell the same products, you won’t have to pay those costs again.

6) Costs, revenue, and profit for an Eight-Piece Clothing Line

Now let’s say that you want to create a slightly bigger clothing line with eight pieces: two t-shirts, two hoodies, two leggings, and two dresses. We’ll assume that you sell 100 articles of each of these eight designs.

You have a bit more money, so you’re willing to manufacture higher quality clothes that cost more but you can sell at a higher price. You have enough money to pay someone to help you with your Shopify setup.

We’ll also say that you even have $1,000 to spend on your marketing. We won’t specify any specific type of marketing here, but at this budget, we imagine it could be either a small amount of facebook ad spending or social media marketing.

Here’s what the costs and revenue of this line would look like:

In this scenario, you need around $25,000 of your own money and make a profit of $3,724 on $29,200 in sales.

Again, if this seems low to you keep in mind that this would be a profit margin of 12.7%, much higher than the majority of companies in the fashion industry.

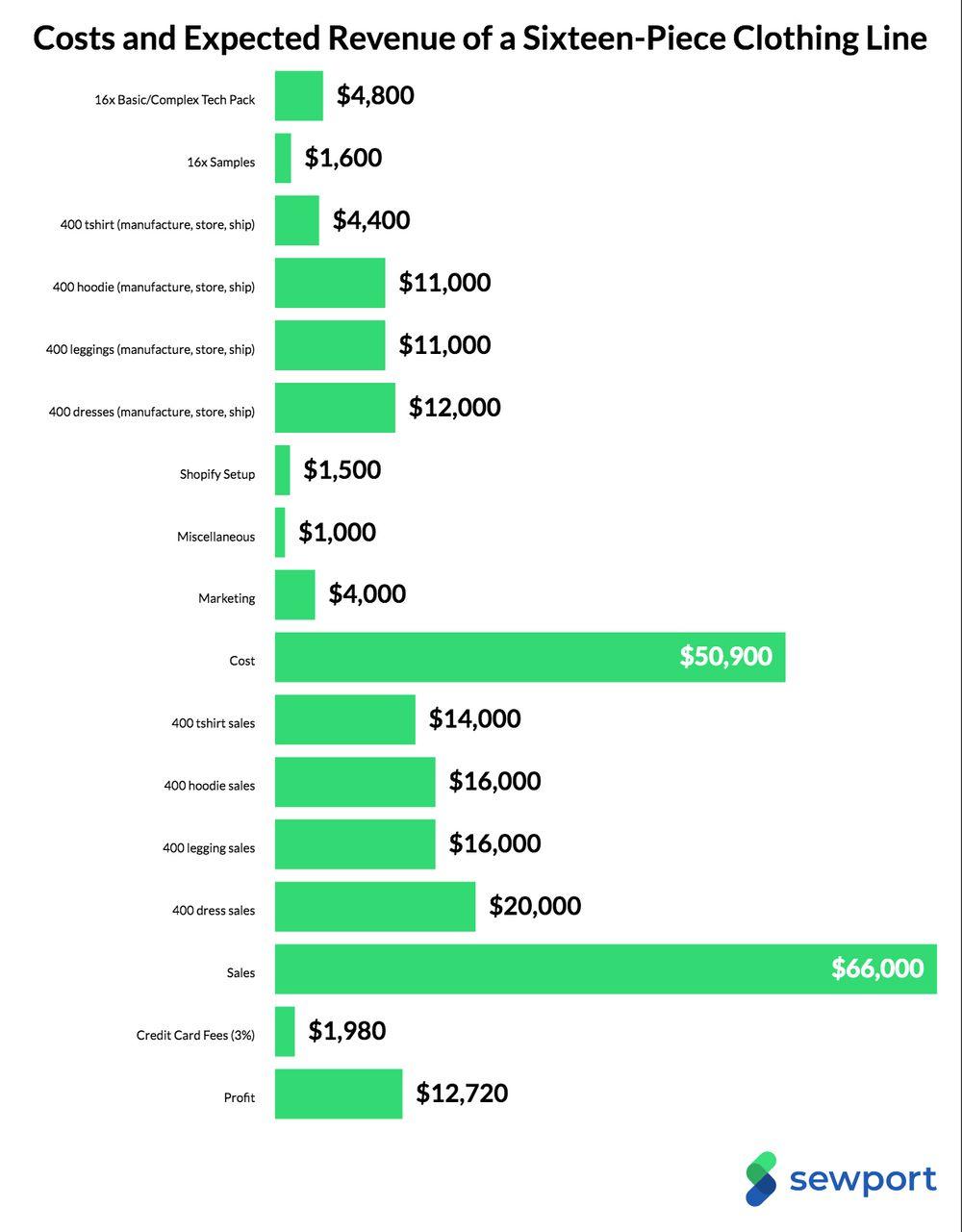

7) Costs, revenue, and profit for a Sixteen-Piece Clothing Line

Now let’s say you want to create a larger, more extensive clothing line. You have enough capital to create a line of high-quality products that cost even more to make but have even better margins.

In this scenario, we assume that you’ll pay $1,500 for a professional-looking Shopify setup. We’ll also assume you spend $4,000 on marketing. Because of your investment, you’ll be able to sell 100 pieces of each design.

Here’s what your numbers might look like:

In this scenario, you invest $50,900 and make a profit of $12,720 on $66,000 of sales. That’s a profit margin of 19.2%.

While that’s higher than the industry average, there are fashion retailers who have even higher margins. With sufficient volume, a profit margin of 15% or higher is definitely possible.

In Concluding of clothing line start-up costs

Business owners must always have a clear understanding of the time and money that must be invested to ensure the success of the business. Long-term finance options, as well as initial start-up funds are essential for planning ahead.

Think of the ways you can financially support your clothing brand. Make the most accurate forecasts of how much money you will need and how long it will last you. Set the goals and hire staff accordingly. Whether investment comes from your own funding or external investors, calculating the return element of this should also feature in your business plan. When financing a full-scale launch of a clothing line, make sure you are funded to at least finish a prototype or sample to show your designs to the world.

Without thorough planning, you will not turn your ideas into a profitable business. So always have a clear plan of actions, base spending of your capital on well-researched pragmatic calculations, not on an emotional whim. Make sure you control the expenses, not the other way around.

We hope that you now have a better understanding of the costs of starting a clothing line. It is a substantial investment, but you’re able to make your money back and more within a few months if you have the customers.

Your next steps should be to figure out what types of clothes and designs you want to include in your clothing line. It’s important that you plan for pieces that are within your budget.

There have been a lot of steps presented here since clothing manufacturing can be a complicated process. Making a mistake anywhere along the way can be the difference between a profit or a loss.

If you want to make the process easier on yourself and also be connected to verified manufacturers, try the Sewport platform out or contact us. After seeing countless brands go through our platform, we’re confident that we have the know how to make your dream clothing line a reality.

4. Execution: Skills and Vision

Research is one of the most important and necessary skills to refine when starting your own business . This is especially true when starting with no experience behind you. Ensure you are crystal-clear on your ideas for your brand. Be able to explain your brand and your products with confidence and assertion, which will make it much easier to secure partners to work with in the future.

Use your time wisely to ensure you have researched in full your product area, the industry as a whole surrounding your product area and the competitors within the market. Many start-ups make the mistake of spending days, weeks or months working on their idea to be told there is another brand doing exactly the same thing, possibly even better than your concept. Ensure you know every competitor in your field, what they do, their product mix, their price points, their suppliers, their customers and their marketing to ensure you start your process one step ahead of the competition.

1) Skill, Education and Experience

Experience counts for a lot when it comes to business. However, there is a plethora of information, both free and paid-for, available out there for you to upskill your abilities and learn about the business world, to compensate for your lack of experience. Dedication is key when setting up any business. However, if you’re starting from scratch without any experience and just an idea, you will have to work even harder to find success.

- Business Courses

Taking an online business course is a fantastic way to give you an overview of what owning and running a business entails if you are starting your journey with no experience in this area. Learning skills in marketing, finance, branding and logistics, a business course will give you practical knowledge that you can use when launching your clothing line and well into the future.

- Fashion Courses

Starting a clothing line does not require you to be a professional fashion designer, although you might want to consider getting a degree in fashion design and consider its costs. However, there are fashion courses available, both in-person and online, that will help you to learn the basics of the fashion industry from design and inception of ideas to literal e-commerce and sales and textile design. Studying a fashion course at a recommended and respected academic institution could also potentially set you up with contacts you would have no way of meeting otherwise.

- Specific Skill Courses and resources

Depending on your individual experience or time you might want to get a fashion apprenticeship and upskill before you move to starting your own apparel brand, there are many online courses to upskill what you know and get valuable information in areas in which you are less skilled. From digital marketing courses to pattern cutting or web development, gaining knowledge in as many areas of your business as you can, will only help you to develop your brand with a better eye and allow you outsource less, saving valuable funds and making better, more knowledgeable decisions along the way.

It may sound like an impossible task but starting your own clothing line without any contacts or experience is possible by using the available resources and working harder than you ever could imagine. Businesses take a long time to get off their feet and reach success, so be prepared to persevere through difficult times and ensure that you can financially afford to be patient when it comes to making profits.

Most importantly, reach out to people , network and use online resources and platforms available to you, such as Sewport , to ensure you are working with the best possible people for your business.

2) Partnering up

When you are starting a new business, you will need to partner up at some stage, whether it is help with design or specific assistance with social media promotion once you’ve launched or anything in-between. If you’re starting your business with no contacts, this might seem like the most daunting aspect of the journey.

Sewport is an online platform, expertly created to help those in this position. Connecting designers and entrepreneurs with the professional partners and suppliers they require to launch their clothing lines, Sewport can introduce you to clothing line manufacturers and garment production factories that would otherwise be out of your reach .

An easy to use, consumer-friendly digital platform, Sewport gives you a login to a set of tools and an account, which allows you to then input your job specifications. From creating patterns and samples from your initial ideas to souring your fabrics and trims and making your garments, you’ll find custom sewing services that can help with your exact requirements.

Clothing manufacturers will be able to contact you about your job and start a discussion about bringing your clothing line to life, allowing you easy access to some of the best fashion manufacturers and small batch factories in the UK and Europe through one streamlined platform.

Boris Hodakel , owner and founder of Sewport , suggested that the biggest mistake entrepreneurs and designers make when launching their first clothing line is “going into business with the wrong people” . Through using Sewport, you can connect with professional clothing factories, verified by the platform and benefit from secure payments through the Sewport system, which offers you a guaranteed level of service unavailable should you attempt to contact manufacturers as a solo business.

Using a platform like Sewport allows access to a range of dedicated and highly-skilled production companies, specialising in both small batch garment production and bulk orders. Without experience in the fashion production business or a circle of contacts to draw on, Sewport is a fantastic way to connect with the professionals you need to launch your business in the best possible way, giving your brand the highest chance of success.

For new fashion start-ups, using valuable resources like Sewport can help them create new connections in the industry. For example, here on the Sewport platform, you can do all of this in one place. Our innovative website brings both designers and suppliers together with easy ways to communicate and develop a business relationship. You don’t necessarily need prior experience in the industry or contacts, as you are able to create a free account, which enables you to talk first-hand to your suppliers and discuss options for developing your brand.

3) Try an online sourcing marketplace to find your manufacturer

For businesses looking to break into the industry, these key introductions could provide a wealth of avenues for new brands. Here at Sewport we give you the chance to focus on other aspects of the business, as you can be confident clothing will be provided on plan and at an affordable price. Our platform is great for designers looking to take the next steps in the industry.

Sewport is an online space where established brands and fashion enthusiasts can bring their ideas to life using intelligent tools. The path from sketch to product leads through layers of service providers – Sewport consolidated these companies to become a one-stop shop. By removing complexity around creating a piece of clothing and improving lead qualification we are speeding up the conversion in the fashion industry.

Both experienced fashion brands and newcomers without any links to the apparel industry benefit from the functionality of the.

We made an expert roundup and asked Minuca Elena to reach out to 43 fashion designers and ask them:

5. Tips: Biggest challenges and tips from 43 Fashion experts

Samantha Giraud

As a fashion designer and couturier building two international brands, I work with a lot of international teams and professionals.

For instance, I am based in Hong Kong and Paris, my design and technology team is in Singapore, and my PR and marketing representation is in the United States, so

Additionally, some of the other largest challenges are to be able to

Olga Kay – Moosh Walks

Moosh Walks today are sold in over 100 stores, Amazon, The Grommet and our online store MooshWalks.com We are high quality, top rated 3D sock company.

However, starting this brand was filled with numerous challenges.

Being a Founder without previous connection or knowledge of the fashion and business world, every step was an uphill battle.

* SOURCING A MANUFACTURE . The hardest part in the beginning was to be able to find someone who can turn the art work into an actual product. We could not manufacture in the states so we took our first time production to China. No factories wanted to produce Moosh Walks because they have never made socks WITH ears before. After 6 rejections from potential factories, we finally landed 1. Alibaba express is a great resource for overseas and MakersRow.com for USA Manufacturing.

* MINIMUM QUANTITIES AND QUALITY CONTROL . We were then faced with high minimums without even knowing that this new type sock style will resonate with the customer. We also opted into making the best quality product which naturally results in higher spend. (Thank you credit cards).

* DISTRIBUTION . Once we had thousands of units the next uphill battle was to convince store owners to carry the product in their stores. To overcome this hump we were offering the store consignment structure and once we knew which store did well we would offer their competitors 90 day by back guarantee.

Bianca Dabney – BIDA Boutique

My biggest challenge in starting a clothing line was finding the right clothing manufacturer. For me, there were many aspects involved in finding the right manufacturer, my top being they must be ethical, help to promote sustainability, provide quality work, easy to communicate with and be trustworthy.

After finding the perfect manufacturer another challenge I faced was demand forecasting for my e-commerce sales.

Distribution also posed as a challenge as it was quite costly and time-consuming to find my niche target market and potential retail buyers.

Playing into this, marketing and pr brought on more expenses than first planned as launching a brand from ground zero takes effort in first finding who your target market is and then marketing to them. You may end up spending more money and giving away more product than originally forecasted.

Erum Ilyas – AmberNoon

I started my own dermatologist designed sun protective clothing line last year.

I specifically choose textiles with UPF protection and only use ones that have sun protection based on the weave of the textile without added chemicals or coatings to achieve the UPF rating. There are many mills that have UPF textiles but it’s not always clear which ones are treated fabrics and also which retain their UPF after washing.

For this, I have taken the additional step (and huge cost) of having the garments tested at laboratories to verify claims. In seeking manufacturers, I have focused manufacturing within the USA and have found there to be many manufacturers that are not only qualified but also reasonable to work with. This has been a blessing given the fact that I am a full-time dermatologist and mother of 3 kids (2 teenagers and one tween) and simply cannot fit the travel abroad into my schedule to oversee.

I started as an online store for a little over a year and have had much success and publicity that has permitted me to gain the attention of large retailers.

With a product such as mine, however, many feel the need to really feel the fabric to make sure there is a soft feel (there is) given the fact that many sun protective clothing companies have a very different feel.

Kaila Methven – Madame Methven

Starting a clothing line can be very challenging from the get-go. Things to consider are production costs , while still being able to sell items at a retail price and still being able to profit. Therefore, it is so important to create your own patterns and research the best production company that allows you to keep your costs low when you’re first starting off.

I was determined to find the best production team,

To conclude there are many obstacles when first starting off, but you have established brand identity it will be easier to research what manufacturers and suppliers are best for you. Most of what I have learned as a businesswoman is from trial and error, you won’t know unless you try.

The Boyz from New York Streetwear

The first thing to understand when creating a clothing line is, you need to have a vision.

Starting your own line consists of many variables and challenges, but taking your time in the details is vital.

When it comes to manufacturing and supply, the wrong decision will crush your vision. The people you associate with and work with will determine your success.

Matthew Wignall – The Gentleman’s Tailor

I have worked with dozens of manufacturers, all over the world, who all claim to be the best in their field, however, there have been many small mistakes throughout production, which has had a negative knock-on effect to our business.

In my opinion, the best manufacturers that I have worked with have been located here in the UK, where we now make all our suits. Intact all our suppliers, starting with the mills, who manufacture our luxury wools, our pattern cutters, who cut a classic silhouette, to the manufacturing of every bespoke garment is crafted locally in England.

Not only does British manufacturing stand up to strict guidelines to ensure the quality is superb, but also if there are any mistakes, we can rectify quickly and with minimum ease, to ensure our suits are finished at the highest quality, but in time, which is critical if we’re facing a strict deadline, such as someone wedding.

We are selling high-end bespoke suits to a discerning British clientele, who on-the-whole know how to identify quality craftsmanship and a well-fitted garment, the manufacturing is key to ensure that our customers are delighted with their purchase.

Julia Goodman – Julia Jolie Beverly Hills

Starting a clothing line: I had a lot of challenges when I started my clothing line. I started my company on a low budget, so I didn’t have the means to fly to China and meet with manufacturers, which would have made the process much, much easier! I went to the website Alibaba and connected with manufacturers in China through them.

I also had to overcome a language barrier, a minimum order per dress requirement, and having to identify quality material from pictures . Sometimes, the sample dresses, that I had waited for months to arrive, turned out to be terrible and I wasted weeks waiting for them.

Finally, your products can be held up for months in customs , and delay the process as well.

Marketing: As for marketing, I sell my clothing line in my online store Julia Jolie Beverly Hills. Marketing online is always a challenge: you need to find your target audience and spend a LOT of money on advertising. Best places to advertise are Facebook and Instagram.

Being a social media Influencer myself, I also tried influencer marketing. The challenges there are: finding the right influencers with the right audience and finding the influencers that convert their followers into buyers.

Erica Waddell

You don’t have to be perfect as long as you are consistent. But it’s difficult to get all of these factors right if you’re just starting out. When starting a fashion line, or any business, it is easy to get overwhelmed because you’re doing everything yourself.

Instead, focus on what you do best or love most. For those other areas, build a network of support as early as possible and start trusting the people who want to help you to give you the help that you need.

Mariatu Turay – Gitas Portal

The biggest obstacle I faced starting a clothing line in the mid-2000s that focused on using African prints to promote African fashion, was challenging the negative mindset around wearing Ankara prints, which are typically bold and bright.

I started at a time when African print wasn’t fashionable outside of Africa and potential customers felt self-conscious wearing the bright coloured and bold patterns in an environment where people’s default is to wear subtle colours and patterns in order to blend in.

However, the issue was more complex than this. The narrative around Africa has persistently and predominantly been negative and this played into the psyche of potential customers at the time.

Time has moved on and today African fashion is popular, with celebrities and major mainstream fashion brands having helped to pave the way for its ascension.

Within the European market it was difficult to find a broad selection of quality prints at the time and I had to source from West Africa. As African fashion has grown in popularity, there is now a plethora of options of ankara print but not other types of indigenous textiles typically produced by local artisans on the continent.

African fashion has somehow been hijacked by ankara print and a lot of designers use this for their collections. This has also created a side market of inferior quality prints from places like China flooding the market both in Europe and Africa.

On the manufacturing side, it’s always a challenge as a lot of factories have closed down over the years with production having moved to places like China, India etc. Though there are some benefits manufacturing in the UK, it’s a catch 22 for smaller brands like us as manufacturing costs are much higher in the UK but the production numbers make it less cost effective to go outside. In addition to this, UK factories prioritise manufacturing for bigger brands as there’s more money to be made.

Finding distribution channels outside of direct channels used by smaller brands still remains a challenge; as does marketing. A lot of it boils down to visibility and the financial cost associated with this in a marketplace that’s saturated with prints and has lost some of its charm and novelty, especially with poor quality imports.

Katie Echeverry – Unique Vintage

I had many challenges (and still do!) when I first started my clothing line.

Finding a reputable manufacturer overseas that would accept small units was very tough . On top of that, it takes 6 months to a year to work out the kinks with any factory. In the early days, I had to accept whatever fabrics the factory would source for me, which left a lot to be desired!

Now I’m able to travel to the largest fabric market in Asia to source my own fabrics which is a lot more rewarding. We still are challenged with finding specialty factories that will work with our low minimums and finding people on the ground in Asia to source for us and do our quality control.

I’m not sure we’ll ever be challenge-free but we get more and more versed as well gain more experience.

Agathe Ngo Likoba – Likoba

The biggest challenge in starting your own clothing line and brand is primarily financial as it is extremely costly if you don’t do your homework, due diligence and coordinate a serious business plan. Most financial institutions consider the fashion business a risk. Fashion is always changing, you have to be able to produce a new collection every season and follow or beat the trends.

In my case, I am kind of breaking the rules and codes. Yes, sometimes you really have to listen to yourself and go through with your idea.

The challenge in having a solid line and brand is to offer a product and an idea that hasn’t been done. To be different, know your consumers and your market.

Then comes the challenge of remaining on top once you are known and renew yourself constantly while having your own signature and style that can be recognized and identified immediately with your name or logo appearing anywhere. That’s why I chose to be a jumpsuit designer and offer high-end jumpsuits and specialize in this area.

Another big challenge most designers will encounter is finding distribution , boutiques that will carry your garments but also simply finding reliable people.

Anthony DeVito – TORCH ELECTREK™

Three years ago I started my own clothing line of heated apparel. I started with one idea- The Torch Coat Heater- a battery powered heater designed to fit in your jacket. With the success of that, my customers began asking for other heated products.

Fast forward to today, I have designed, sourced, and manufactured my own line of heated apparel including a heated base layer shirt, heated gloves, heated insoles and a heated back brace.

I am kind of one-man show when it comes to all of this. I love developing products and designing outerwear, all of the products on my site were designed by me!

My biggest challenge right now is getting my manufacturer to deliver the products on time. My manufacturers are in China, and it’s somewhat easy to communicate through email and Skype and I often end up staying up until 4am as the time zones are so different here in the US.

I have a very seasonal line of clothing, and they are late with everything. Because of this, I will have to source new manufacturers next year. I relied to heavily on one manufacturer and my plan next year is to spread out to 3 or 4 manufacturers in case any of them encounter a problem.

Ann Mahoney – Peeky Designs

1. Biggest challenges : For me it was finding materials. I found I had to create my own little fabric-seeking mafia. But it took me SIX MONTHS to find that source!

2. Finding Quality Materials : Ultimately, we decided that going with fabric made in the USA was the quickest and most efficient way to go about this. It IS NOT the most cost-effective way.

3. Cut and Sew Procuring : This was also challenging. As a new designer, having a pattern made by someone else, having the cut and sew work done out of town, that scared me. I had to see a guy about a guy who might have a cut and sew factory. After several phone calls to local boutiques, found out a company had been the head of cut and sew with Burberry! The samples were PERFECT and we immediately went into production. But it took me 6 months to find her!

4. Marketing continues to be a challenge . I am a successful actress, but I am nowhere near Kanye West successful, we still have not figured out how to get the word out to BUYERS. The people who have seen the brand and the Fall line LOVE it, and are always saying how we are a niche style that people WANT. But we haven’t yet cracked the code on how to get people buying.

5. Distribution : We are using a many-headed hydra approach to distribution right now. We sell online through our website. As the head of the company, and an actress from THE WALKING DEAD, I am bringing garments with me to the comic cons I attend as a celebrity guest. We are approaching boutiques in New Orleans, where we are headquartered, and boutiques in Los Angeles, NewYork, and Canada, about selling PEEKY in their stores.

Ruby Bhandari – Silk Threads

Creating a fashion line has been really fulfilling for me – however, creating the line is not for the faint of heart! You have great design ideas, but can you commercialize those? How would you do the production, and can you meet the deadlines? How do you guarantee the quality your clients expect from you? If you are doing production offshore, do you know the rules around importing and distribution?

I could go on, but these are exactly some of the challenges I faced when I was starting and growing Silk Threads, my line of custom dresses, bridals and menswear. I have learnt a lot about these challenges and more over the years, but

Tara Sauvage – Two Neighbors

The biggest challenge for a contemporary fashion designer in the apparel world is, as a start-up, they only want to produce a limited edition of apparel, but that means producing in NYC or LA where the costs are high.

New Designers cannot compete with fast fashion so they have to have a very unique look or a higher price post to produce in the USA and attain customers.

Overall, the biggest challenge is getting start-up money and dealing with production issues , to produce in China or the USA. Producing overseas affects the branding, the retailers, the price point and more.

Rusty Meador – Beach & Barn

When we started, we had a good concept, good branding, and a modest social media following. Our biggest challenge was clothing education. None of us had an apparel background. T-shirts and hats were relatively easy because we could source blanks, but moving to a cut and sew polo and sport shirts required a professional designer and the need for more sourcing options. Once we found the right designer, we had to find factories that could work with our small MOQ’s and quality demands.

Cash was always a concern early on. We tried a lot of “print on demand” options early on to alleviate the inventory demands. Ultimately that was inefficient, expensive and a poor option – so we rented a warehouse, bought some used shelving, and wifi hotspot. We went through 4-5 different t-shirt blank t-shirts before we settled on our standard. 50% of our distribution is direct to consumer via the internet and 50% is through a wholesale network – which is roughly 25 retailers and growing.

Jake Smith – Smithers

Given the popularity and global praise for Australian-made swimwear, you’d think it would be easy to start a new label, right? Wrong! The swimwear community here in Sydney is tight-knit, and this became very clear when I set out to build a men’s swimwear label. People are very precious with their time so gathering information and resources was a challenge of its own . Nobody was willing to give up too much unless they thought you were serious about pursuing a swimwear line.

I ended up leaving Sydney to meet with suppliers and manufacturers in Asia, however, I quickly realized that I’d have to make a lot of compromises, particularly on the quality of fabrics and raw materials. I returned to Sydney better informed and with a strong determination to make things work on home soil.

I spent the following months meeting suppliers, manufacturers, pattern makers, graphic designers, and printing houses. My determination had paid off, I was able to crack the industry and surround myself with the right people to bring my dream to life.

Before too long, I was faced with more bumps in the road. As the new kid on the block, I went straight to the bottom of the pecking order; delays, delays, and more delays. Initially, I was frustrated; my money was just as good as anyone else’s so why did I have to make way for bigger brands?

Misha Kaura

My biggest challenges of starting a fashion line centered around not living in a major fashion center . When I started my label, I was living in Portland, Oregon, and then later in Seattle, Washington. I was regularly flying to Los Angeles and New York City just to get needed materials and then all over Europe and Asia to get remaining fabrics and trims. I also had almost no colleagues in my industry back in the Pacific Northwest.

All of these problems were eliminated within seconds of arriving in New York City. Though this is a massive city, I have already made lots of other brilliant designer friends and learned all about various shops and resources in the Garment District.

I wanted to be in Seattle because I love outdoor sports and the low cost of living, but I ended up spending triple my rent on flights alone and found that it’s actually much more expensive to live in a non-central city and fly everywhere. As much as I love the Pacific Northwest, I think it’s important to be in a fashion community.

I have already set up a fashion mastermind group for my new friends and I, and together we are all making our dreams come true in this field. There is a big media misconception that fashion is competitive; honestly, the nicest and smartest people in the world work in fashion and everyone is so collaborative and always gives advice and wants to help emerging designers. You learn so much more just being out and about than you do being isolated far from your colleagues.

It’s amazing to be in New York City and have the kind of creative community everywhere you go, from the whipsmart journalists to the friendly buyers, to managers giving tips and advice over coffee. I feel being around greatness makes you work harder and refine your vision and your message to your customers.

The City itself and the whole business community at large is so welcoming and it’s amazing—I’m so lucky to be in the best industry, with the best people, in the best city in the world. I couldn’t see myself doing anything else!

Sherri Dombi – Bee Yourself Apparel

I started Bee Yourself Apparel because a friend of mine could not find clothes that her dad wanted to wear. He was still attending church each Sunday and going out to eat with the family. His struggle was dressing with buttons and zippers.

She did find a line of clothing, but the fabrics were more like uniforms. They were heavy and not soft to the touch. I knew I could improve on what she found, but having no knowledge of the fashion industry, how was I going to even get started.

I finally found someone to make my patterns from the ideas I had. She made samples and I took them out and test marketed them to caregivers. It was well received so now how do I find someone to manufacture them.

I really wanted a Made in the USA label. Later did I find out that sewing is a lost art in the US. To manufacture here would cost me a fortune and my price tags would be out of reach for most of those needing this apparel. I hired a consultant to help.

We found a company in Columbia that could do pants, tops and my dresses. They sent samples and the quality was great. I think hiring the right people who know the industry is key. Also, be patient. Take your time and do it right.

Mehri – Maraley

I am a fashion designer in heart and in training. I love creating beautiful designs for professional women and that part comes to me naturally. An inspiration comes out of blue; I just see my designs in my mind before I sketch them.

The part that didn’t come easy is learning how to promote it. I do believe my pieces are gorgeous.

The question was how to make other women feel the same about my products?

Many fashion designers and e-commerce owners believe that when they design a beautiful website, upload their products, create their social media profiles and hit that launch button, sales will automatically start rolling in.

Actually, this is where it all begins. And this is where you need to push yourself even harder than before. Getting through that fear of not being liked, bothering too much, sounding too salesy. Regardless of whether you send out the weekly email newsletter to your customers, promote through social media channels or reach out to journalists and magazines, what helped me in my journey was my shift of mindset.

Getting over that mindset that people didn’t want to hear from me and know about my collection. And that became possible for me when I stopped assuming in my mind what they will think and acted in spite of my fear and doubts by just getting things done! One little imperfect action per day.

“Doing one little thing each day that scares you”,- as Eleanor Roosevelt said so well, is what will move you forward, push you out of your comfort zone and take you to the next level of success.

“Don’t let your fears stop you to become what you want to be! Because you have so much to offer to the world”, would be my advice to all fashion designer start-ups out there.

Tamara Bodnarova – TAM ARA

Our brand TAM ARA is a young slow fashion designer brand from Prague, Czech Republic. The biggest challenges for us are the following:

The region of Central Eastern Europe – consumers and clients accept slow fashion and sustainability lifestyle trends slower comparing to Western Europe and it is hard to show them the importance and advantages of high-quality natural materials (we don’t have such problems in Berlin where we also sell our products in various boutiques)

Our target group, especially women 40+ are not active on social media or are less digital savvy than the same target group in the West, so our digital marketing efforts are not meeting the target group.

The inspiration of our designer is timeless and not dependent on the latest trends in fashion or fashion design. Since top designers boutique in the region usually copy paste these international trends and only selects those designers complying with the latest trends, we are sometimes struggling with being told how we should design our garments .

Since we only select high-quality materials and always reward fairly all people working for the brand, especially our tailors, the price of our models reflect this attitude which is often not understood by customers from the region who are still big-brand and consumerism driven and as a paradox able to spend much bigger money for products of big brands, like Gucci, M.Kors etc.

In general, our products have better acceptance abroad than in the country.

Nathan Walworth – CôVALENCE

Our biggest challenges included finding up-cycled and ethical materials for our accessories and apparel that we could produce at scale.

Although the fashion industry has a wealth of excess wasted materials, it has been difficult to track down sources that capture waste streams and consolidate them into a single platform.

The other most challenging component of starting a fashion line is balancing pools of funding for product development and brand creation/marketing strategy. Both have been very resource-intensive for a small collective starting out which has forced us to be very resourceful with creating content and strategy.

Often time, help has come from friends and colleagues in the space willing to lend a hand as we were starting out.

Tori Famuyiwa – Toriola

My motivation to design came straight from a deep, passionate love for clothing, colors and anything that was out of the box. From the age of 10, I felt compelled to create and modify clothes for myself and my siblings.

I started Toriola in the spring of 2010, where I taught myself how to cut, sew and manipulate fabrics. As a self-taught designer who is passionate about creating, my biggest challenges were meeting the demands of the business as it rapidly grew unexpectedly . I found myself sewing all day and night to meet order deadlines for clients both domestically and internationally. I immediately had bulk orders from small boutiques, so I worked to meet those demands while looking into cost-effective options to outsource the labor without compromising the quality of the product.

Starting a brand in NYC was great because of the opportunity for visibility, but sample makers were expensive given the high demand for their services. This became a challenge because I hadn’t factored in this cost when establishing Toriola. In hindsight, I should have hired a business manager to help me handle the business plan, finances, communication, and other logistics.

While in my second year of designing, I took some sample making classes to enhance my skills in order to produce more desirable garments. This is where I learned what tools were necessary to streamline my creative process. This helped produce a more refined and finished product.

Lastly, finding the right web team and digital marketing partner helped me achieve optimal exposure. Other challenges included managing administrative aspects of the business, handling inquiries from media sources, planning and executing lookbooks and editorial campaigns, and creating compelling fashion shows.

In the end, it was all worth it!

Heather Hadwen – HeatherLeigh Swimwear

Among the many challenges that come with starting a clothing line, the biggest challenge for us was understanding and adhering to import and export requirements. I’ve worked in senior-level positions as a Head Designer in the corporate world for nearly 10 years and never knew all of the small to major requirements it takes to manufacture in another country other than your own.

The first challenge was care and content labels, these have very special requirements. Not to worry so much here though, manufacturers are extremely helpful with ensuring a label has all necessary info.

The most complicated challenge was the import broker and courier whom you must line up to receive and remove your items off the cargo ships. During my first production run, I was clueless about this process and needed immense help. Thankfully I had a long-running partnership with the factory from all my years in the business and they were kind enough to guide me through and help.

The lesson learned and my advice to anyone with or without experience is to have the factory review a step-by-step guide of what a start to finish production run entails.

Brian Lim – iHeartRaves

In the beginning, one of the biggest challenges of starting a clothing line was having enough money to fund all of the expenses . I started out with $100 selling items out of the trunk of my car. I was able to grow that into a multi-million dollar business with over 55 employees.

Another challenge, in the beginning, was distribution . Once we had built our website we knew our distribution channels would have to be able to keep up with demand. We began as an eCommerce store and have remained that way because we’re able to handle our own distribution, rather than putting our products into physical stores.

Our third challenge was orking with good manufacturers . Finding reliable people who could handle producing our designs was quite a task, but we were able to do it.

One other big challenge is promoting our product lines . Marketing is responsible for a large piece of our budget and takes a lot of resources and time.

Patrick Morrison – Furious Goose

As a new silk accessories business, without the capital or business requirement to place large orders, it was initially very difficult to find a supplier in the UK who would help us achieve the highest quality digital print . Thankfully, after a search of about one year, we found our perfect factory.